What the difference between Oil-Free and Oil-Injected Screw Compressors?

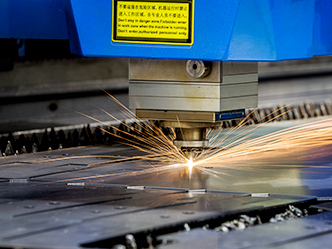

Rotary screw compressors are commonly used in a wide range of commercial, industrial, and light manufacturing applications that range from 3hp to over 500hp. A conventional rotary screw compressor employs two intermeshing rotors in a stator housing that has an intake and a discharge port. Also referred to as helical screws, the rotors interlock precisely and spin at high speeds, in opposite directions.

One of the rotors pulls the air in through the intake port, which is equipped with an air inlet filter that prevents airborne particles to enter the compressor. Then, both rotors push the air toward the discharge port.

Because the distance between the rotors decreases gradually, from the intake port toward the discharge port, the air is captured in a “pocket” as it moves down the axial length of the screws and forced (compressed) into a smaller chamber. In a continuous process, the compressed air is discharged from the opposite end of the intake, as new air is drawn in.

Types of Rotary Screw Compressors

Rotary screw compressors are divided into two main categories: Oil-injected and oil-free.

Oil-Injected Compressors

In these compressors, oil is injected into the compression chamber to lubricate and keep all the elements within permissible operating temperature limits. Although oil is the preferred choice because of its lubricating and sealing properties, synthetic lubricants are also used, particularly in applications that involve higher temperatures.

Using oil or other lubricants as a medium of heat transfer to remove some of the waste heat resulted from the compression process will reduce the amount of vapor in the compressed air or gas. This will minimize leaks from returns into the compression chamber during the discharge. Some compressor models also include a fan on the drive motor shaft that provides airflow in order to cool the lubricant as well as the other elements of the compressor.

To remove the lubricant from the compressed air or gas, most oil-injected compressors use a centrifugal separator. However, a small amount of lubricant or oil (oil carry-over) often passes through the separator, together with the compressed air or gas. The oil or lubricant is filtered and cooled before being re-injected into the compression chamber. In applications that require compressed air or gas at lower temperatures, the air or gas can be run through an additional aftercooler.

Oil-Free Compressors

In oil-free rotary screw compressors, the rotors do not come into contact to create friction. Thus, they do not require lubrication within the compression area. Because the compressed air or gas is completely oil-free, these compressors are suitable for applications that cannot tolerate contamination of the compressed air or gas with oil or other lubricants.

However, the bearings must be adequately lubricated. The lubricant will protect bearing surfaces against corrosion, reduce friction, inhibit wear, and ensure efficient and reliable operation.

Because oil-free compressors tend to heat up fast, compressing air or gas in just one step can raise the temperature above the limits recommended. To avoid this—as well as any potential leaks in the compression chamber during the discharge—compression is done in two stages.

Each stage compresses the air or gas gradually, by several bars; the air or gas reaches the desired pressure level at the end of the second stage. To further remove the waste heat, most designs are built with an intercooler between the two stages and an aftercooler after the second stage.

SCR focuses on the research and development, manufacturing, sales and service of industrial air compressor. SCR has 16 years experience and work with Iwata to create a new technology and quality system .China SCR screw compressor is more efficient, and energy-saving.

High speed direct drive twin screw oil-free air c

High speed direct drive twin screw oil-free air c Air Tank

Air Tank Low pressure Permannent Magnetic VSD screw air c

Low pressure Permannent Magnetic VSD screw air c low pressure Two stages screw compressor LH/LHPM

low pressure Two stages screw compressor LH/LHPM  Permanent Magnetic VSD Screw air compressor APM s

Permanent Magnetic VSD Screw air compressor APM s Permanent Magnetic VSD Screw air compressor EPM/E

Permanent Magnetic VSD Screw air compressor EPM/E Oil Free Scroll Compressor XA series

Oil Free Scroll Compressor XA series Permanent Magnetic VSD Screw air compressor PM se

Permanent Magnetic VSD Screw air compressor PM se