-

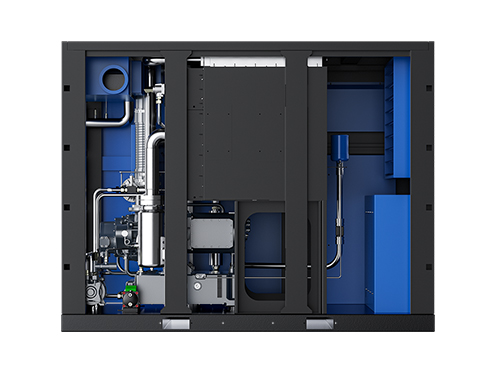

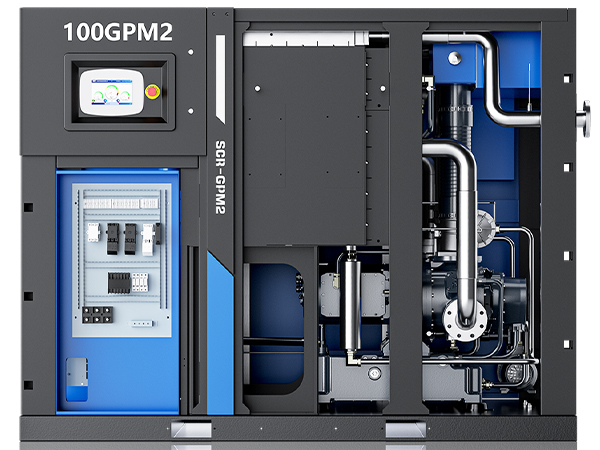

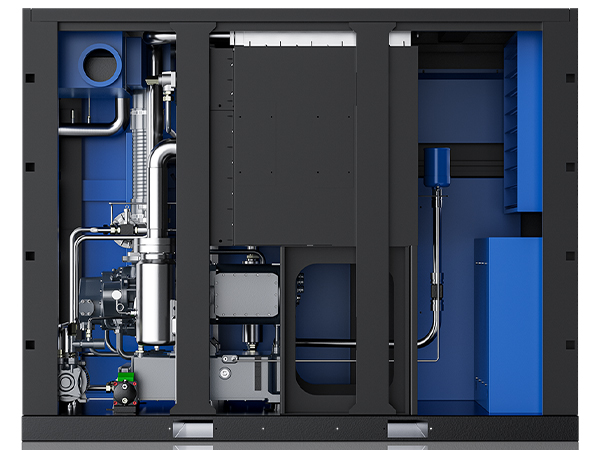

1 New high-speed direct drive system

Energy efficiency improved by 3.5%

Direct drive reduces gear transmission and coupling transmission loss, increasing energy efficiencyby about 1.5%

The body is equipped with dual permanent magnet motors, which increase motor eficiency by 1%-2%

The first and second stage speeds are adjustable, effectively solving the problem of medium pressure rise and increasing energy efficiency by 1%

-

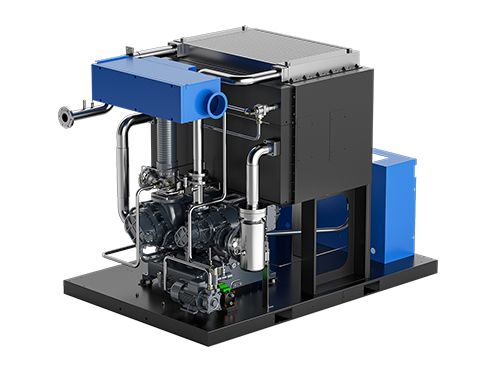

2 IE4 Energy Efficiency Permanent Magnet Motor

Ensure low-temperature operation of the motor within the full frequency range

High starting torque

IP65 protection level, fully enclosed structure with anti wave, anti strong water spray, dust tightness level

Oil cooled permanent magnet motor

Using 180℃ high-temperature resistant permanent magnet materials to ensure non demagnetization

Bearing less and maintenance free design

F-class insulation level

-

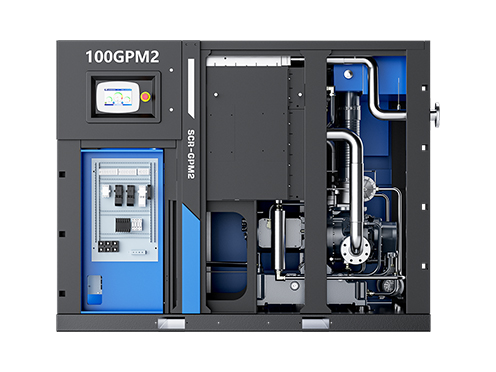

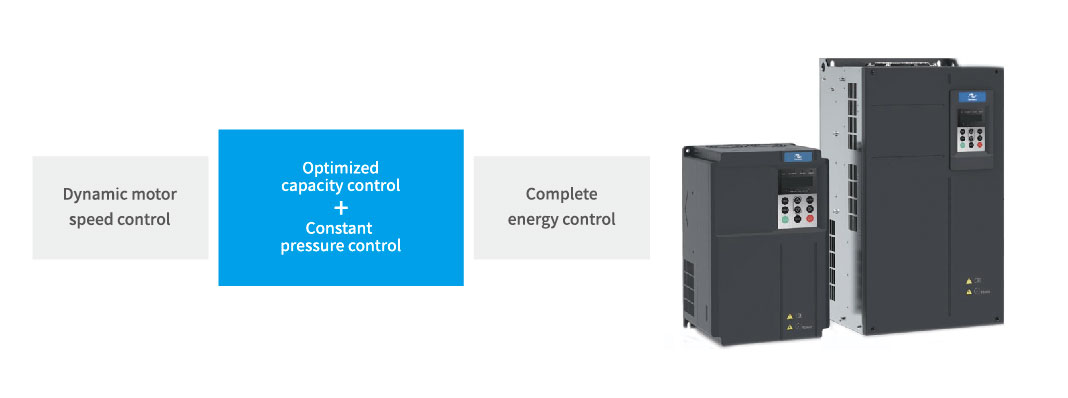

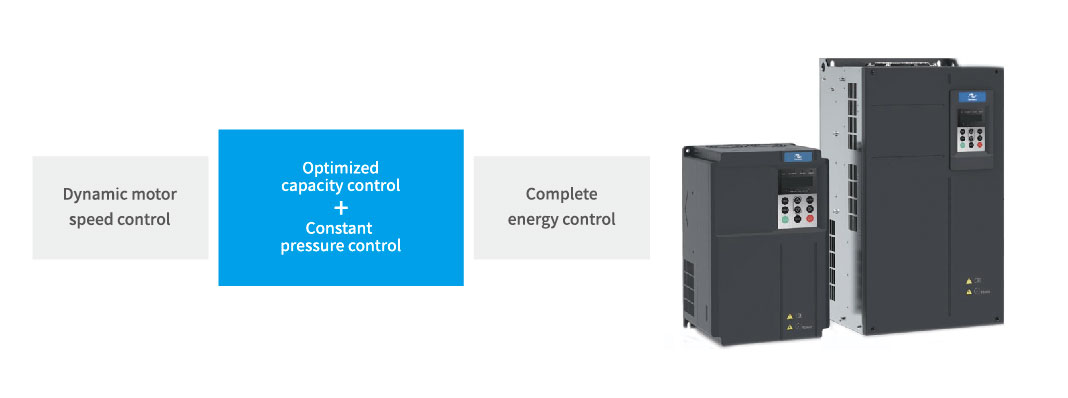

3 Inverter control

SCR EPM2 compressors have a wide operating speed range leading to stable constant pressure control further reducing power consumption. SCR’s exclusive inverter and Energy Saving Logic control can get optimized energy savings, regardless of the load condition. They can react to pressure changes quickly maintaining pressure fluctuation to ±0.01 MPa.

-

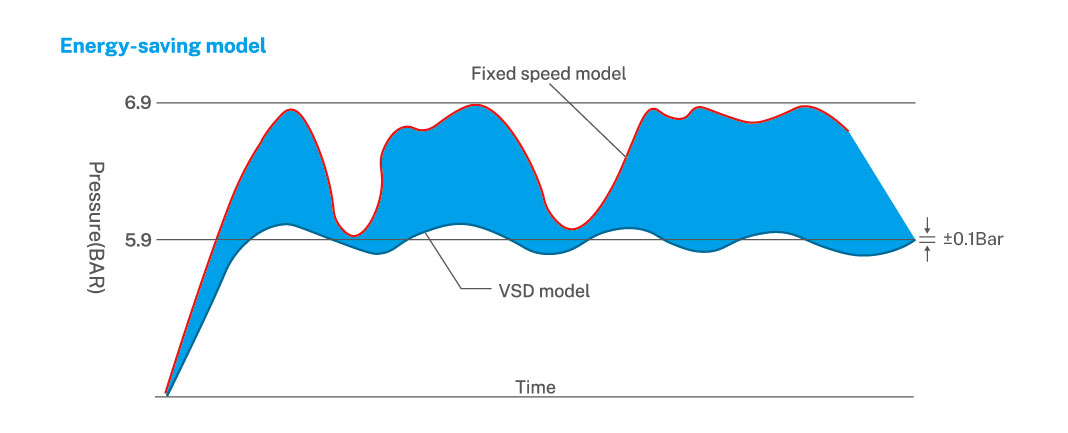

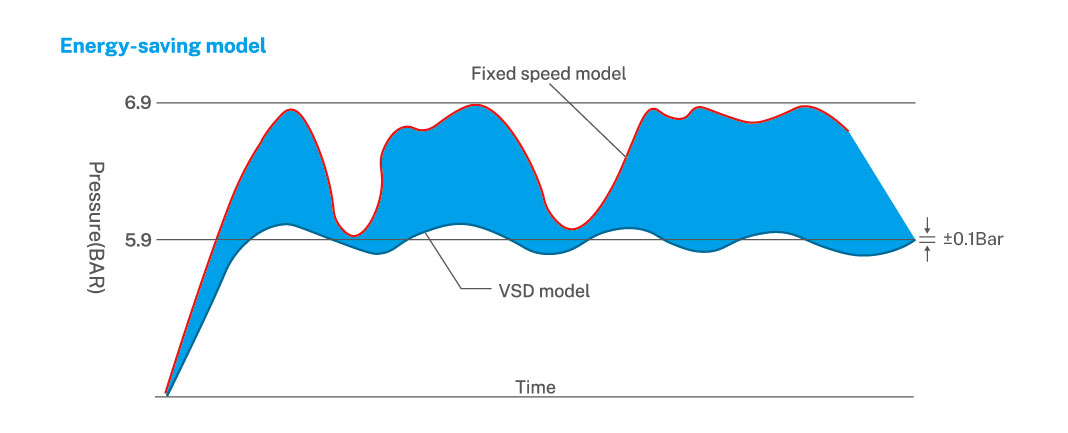

4 Constant pressure output

Significant energy-savings can be achieved by constant pressure control avoiding pressure fluctuations controlled to within±0.01MPa.

-

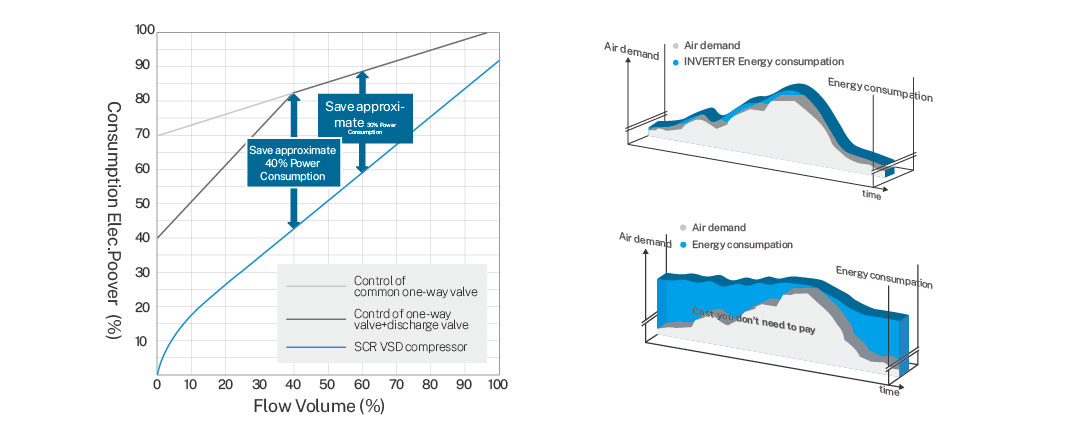

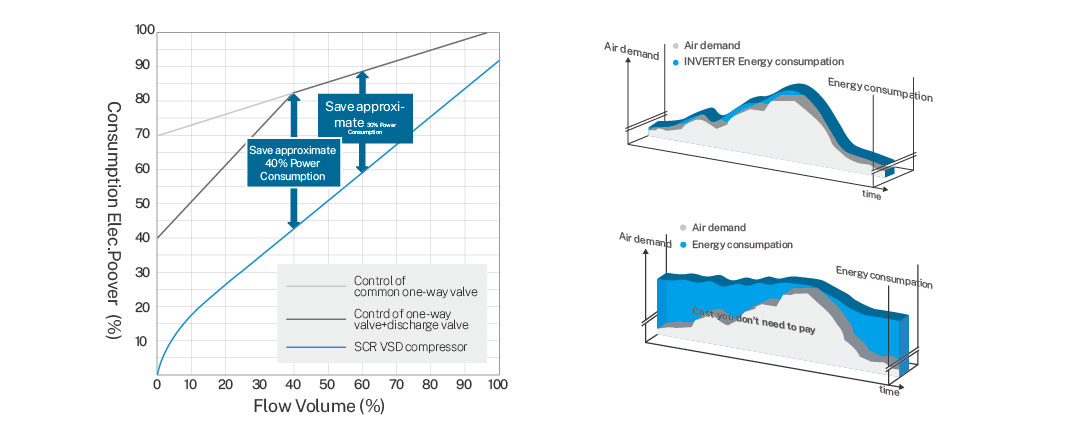

5 Only pay for the air you use

SCR's GPM2 series of compressors adjust compressor's rotating speed depending on the demand, which can change from moment to moment. Thus, it can provide exact volume and pressure what customer needs and achieve maximum energy saving potential. Maximizing energy-saving under any load operation through wide-range inverter control. Wide-range control and Emergency stop function.

-

6 Intelligent control system

· Exclusive invention patent for air compressors by SCR

· New intelligent controller

· High reliable Air compressor

· Multiple Air compressor joint control

-

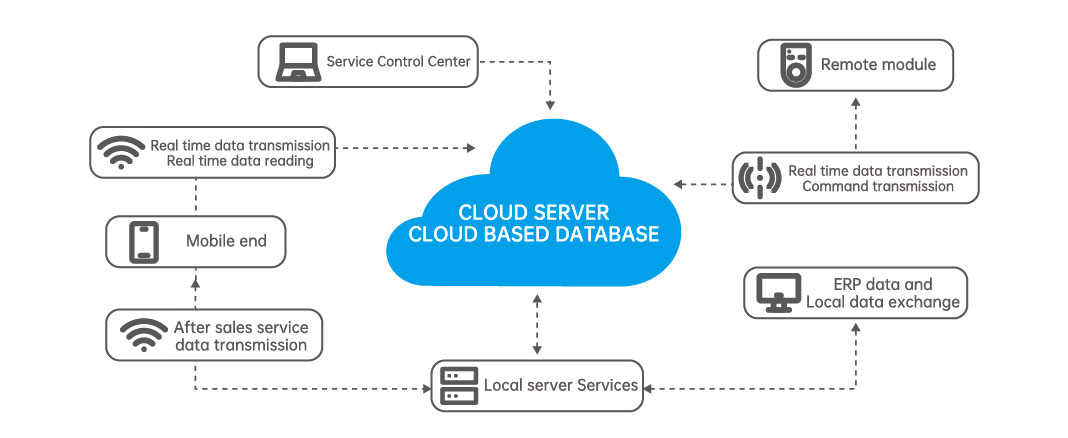

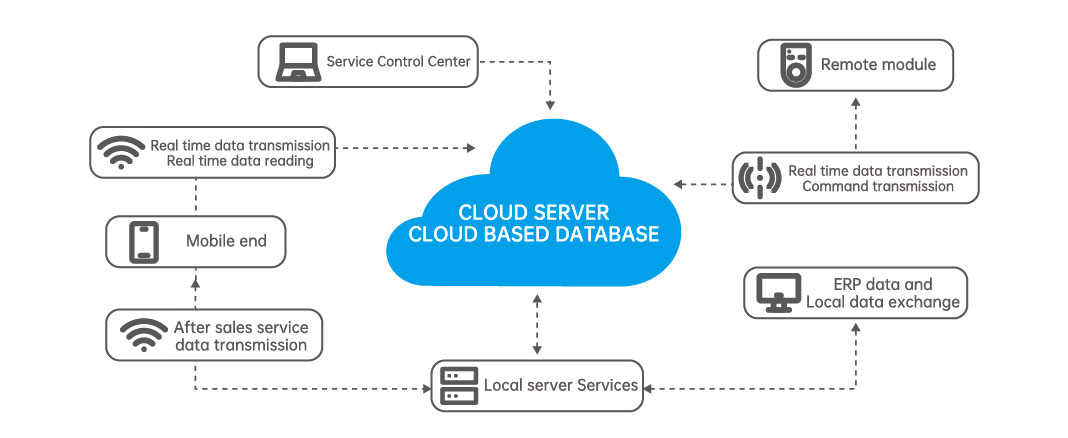

7 Cloud based intelligent control

By using a mobile app to achieve remote visual functionality, you can monitor the air compressor system in real-time even from thousands of miles away.

Potential fault warning function, the intelligent system will send you potential fault information through the mobile APP, allowing your air compressor system to shift from fault repair to preventive maintenance, thereby greatly ensuring the continuous and stable gas supply of the production system.

Powerful historical data storage function, comprehensive storage of operation reports, analysis and control of various important data of the air compressor system, comprehensive grasp of the operation status of the air compressor system, and safeguard your air compressor system.

The intelligent system detects subtle changes in gas usage and keeps the air compressor in a better operating state, achieving an unimaginable energy-saving experience.