- home

- About us

Company ProfileclientsHonors & CertificatesCompany Tourvideo center

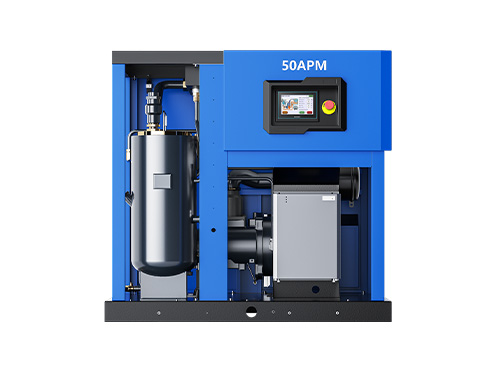

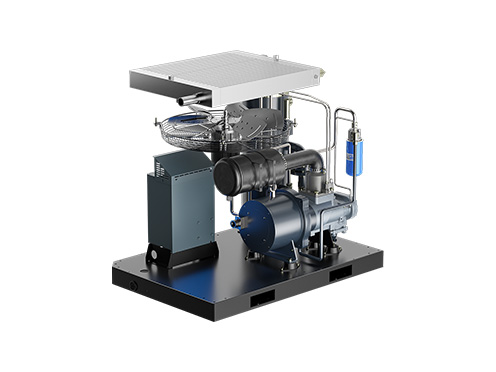

- Products

Oil Injected Screw Compressor PM SeriesOil Injected Two Stage Screw CompressorOil Injected Low Pressure Screw CompressorOil Free Air CompressorOil Free Nitrogen CompressorMagnet Bearing Turbo Blower & CompressorOil injected VSD Vacuum PumpDiesel Portable CompressorDownstream Equipment

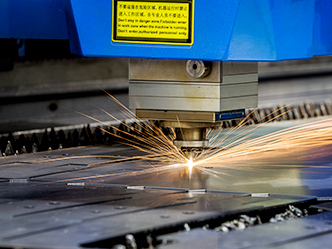

- solutions & cases

Pharmacy IndustryManufacturing IndustryPower Station IndustryCement IndustryTextile IndustryAutomotive IndustryHealth Industry

- Distributor

- Service

- News

- Contact

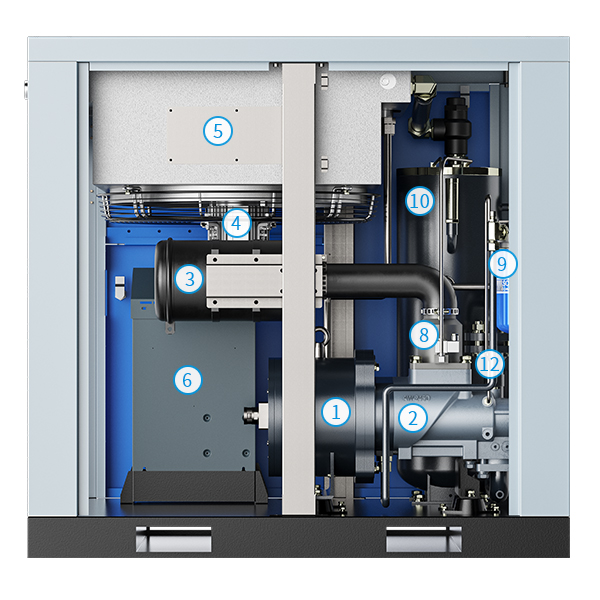

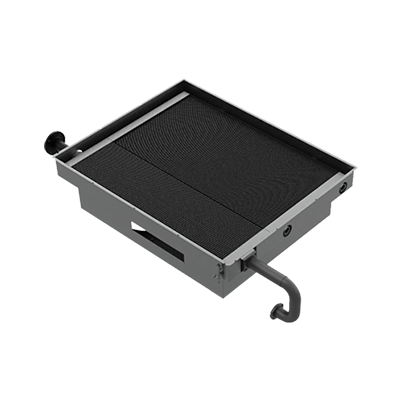

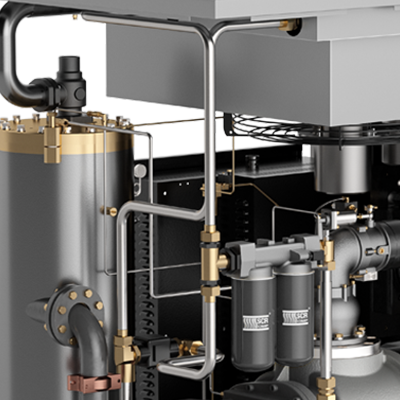

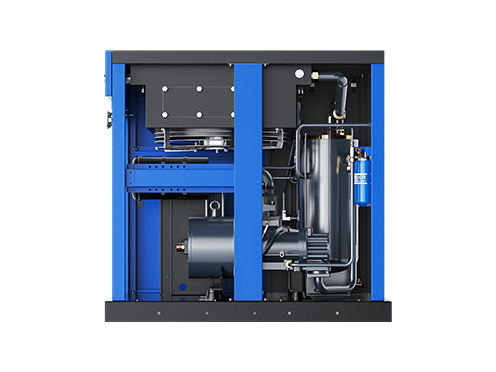

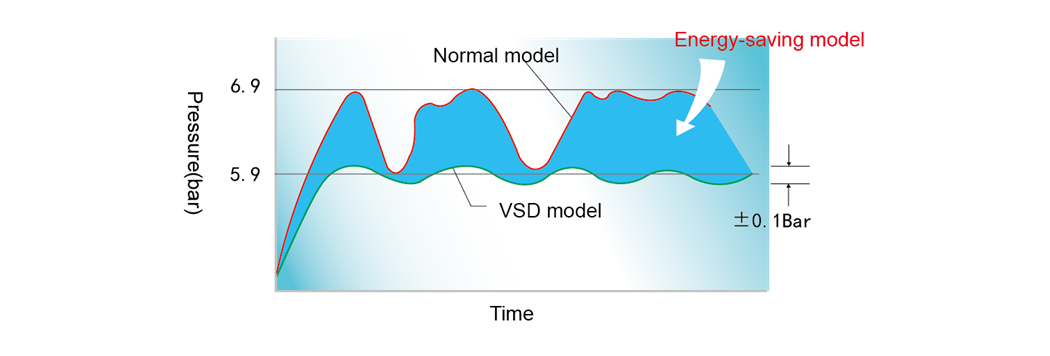

High quality reliable dryer

High quality reliable dryer High precision triple filter

High precision triple filter