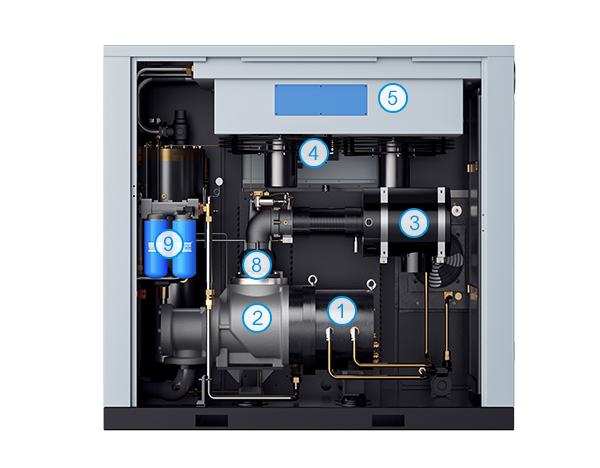

-

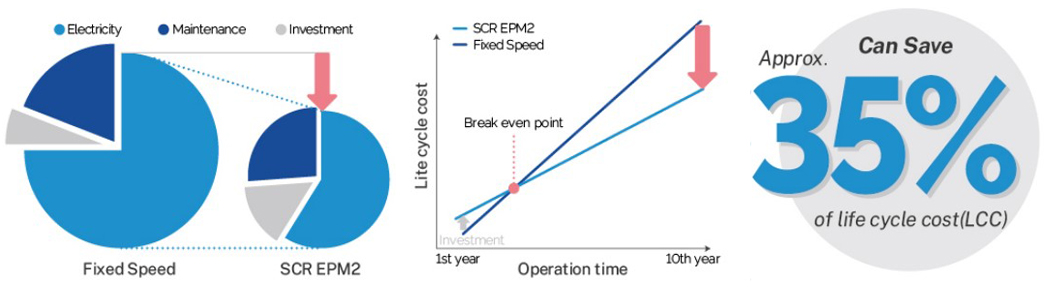

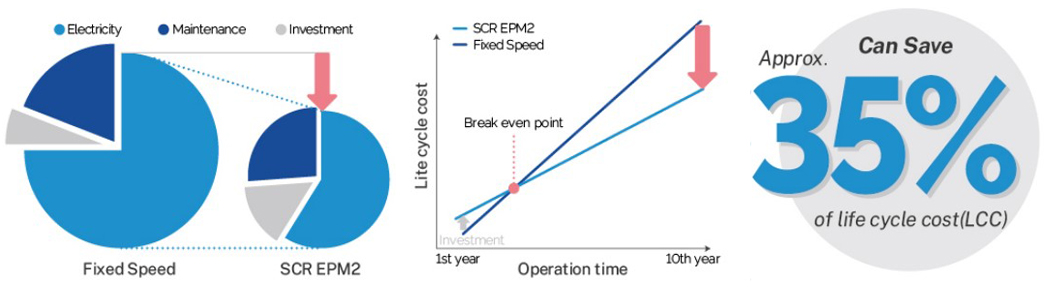

1 Down-to-earth investment for the future

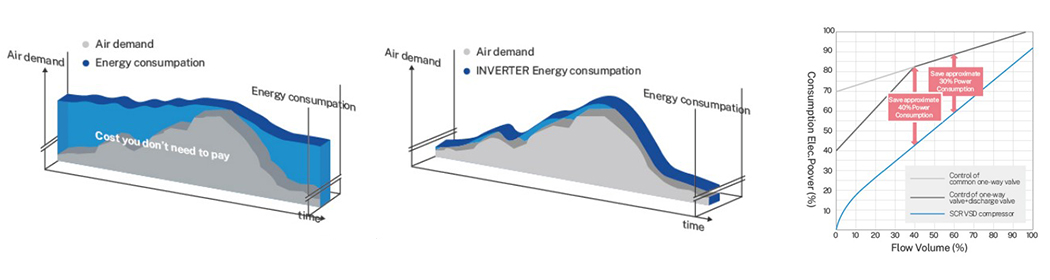

What's important is not initial cost but life cycle cost . INVERTER compressrs may look more expensive than fixed speed model, but many customers choose them because they know importance of life cycle cost & return on investment when it comes to choosing compressors.

-

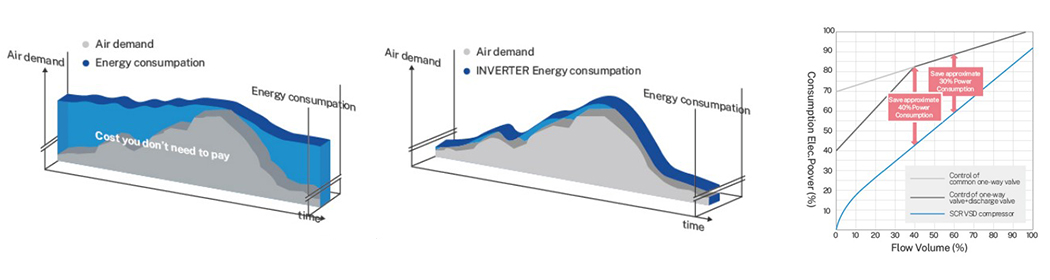

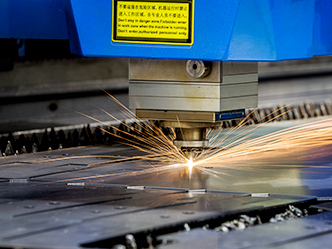

2 What you pay should be only for what you use

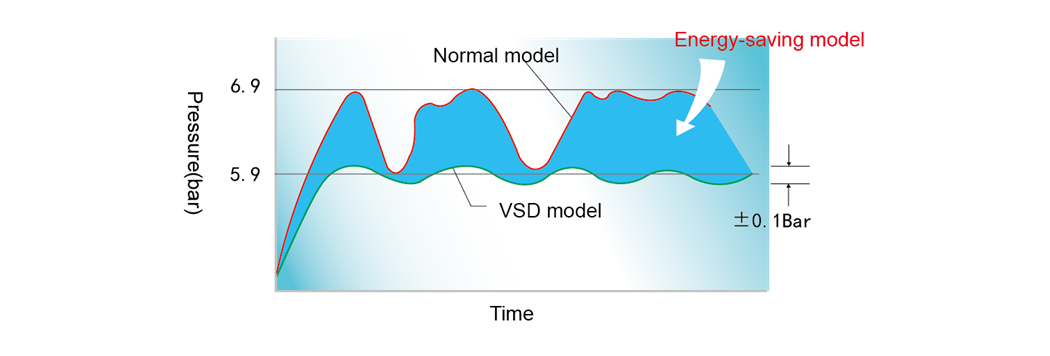

SCR compressor can adjust compressor's rotating speed depends on the demand of factory load which changes from moment to moment by own developed algorithm. Thus, it can provide exact volume and pressure what customer needs and achieve maximum energy saving.

Achieve an energy-saving effect under any load operation through wide-range inverter control, wide-range control, and e-STOP function.

-

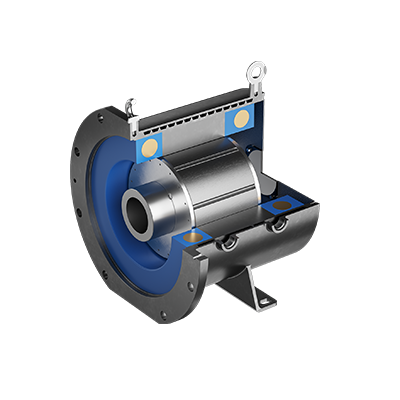

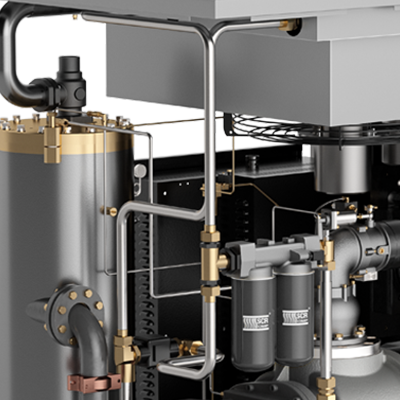

3 Innovative motor oil cooling technology

Independent closed loop cooling, Special coolant,Independent fan

-

4 Special morse connection

Motor rotor is directly mounted on the shaft, No gears or belts, no shaft seal,no coupling, Zero transmission loss, Easy for installation and dismantlement, No need to make adjustment, Better protection for inner parts of PM motor, Reduce maintenance cost.

-

5 Double Frequency conversion system

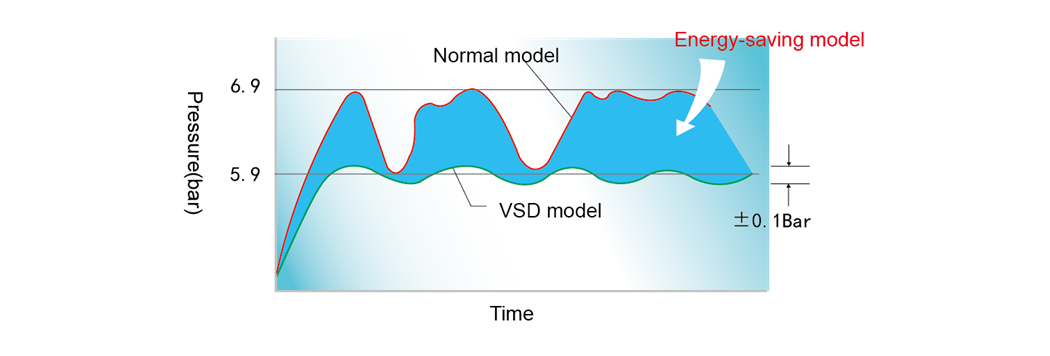

Constant pressure output:

A significant energy-saving effect can be achieved by constant pressure control Pressure fluctuation can be controlled within士0.01MPa.

Constant temperature output:

Normally the temperature is set at 81℃,ensure the best lubrication performances while avoid the sudden stop caused by haigh temperature.