-

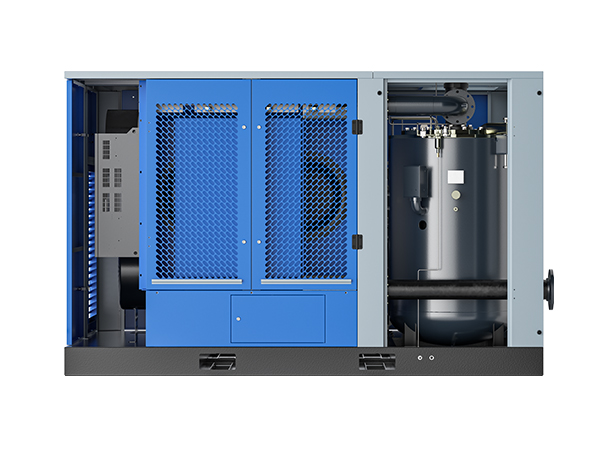

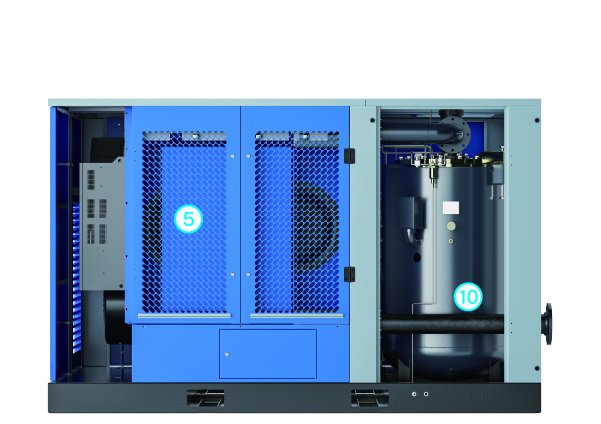

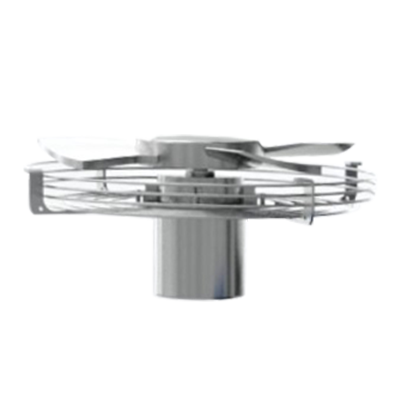

1 Low pressure customs airend

High efficiency Airend profile, specially design for low pressure application, like textile industry, cement industry, glass industry etc, Big airend with low RPM to help get better performance, max. RPM is around 1500RPM, extend life span of airend.

-

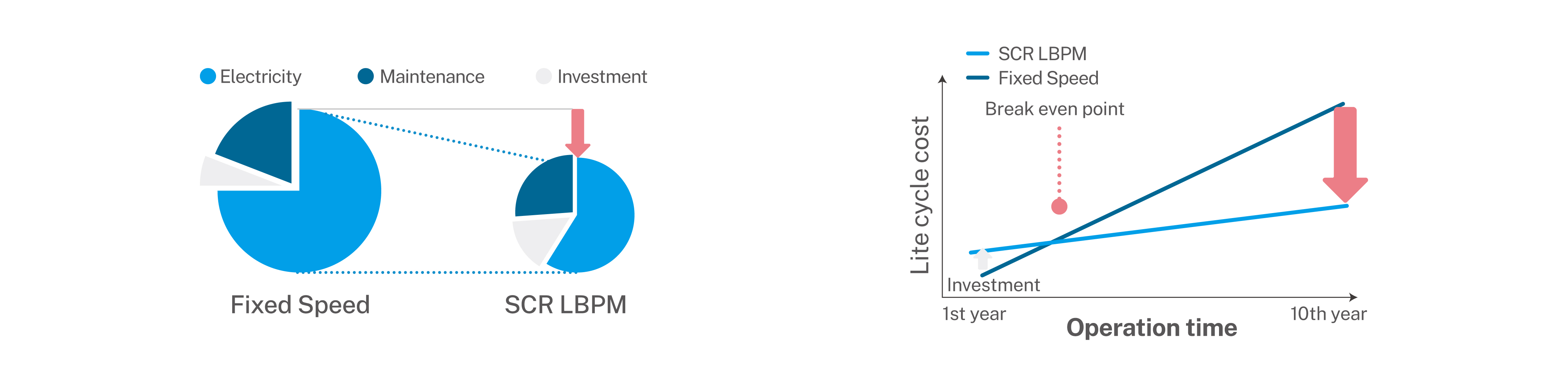

2 2.High efficiency PM motor with VSD technology.

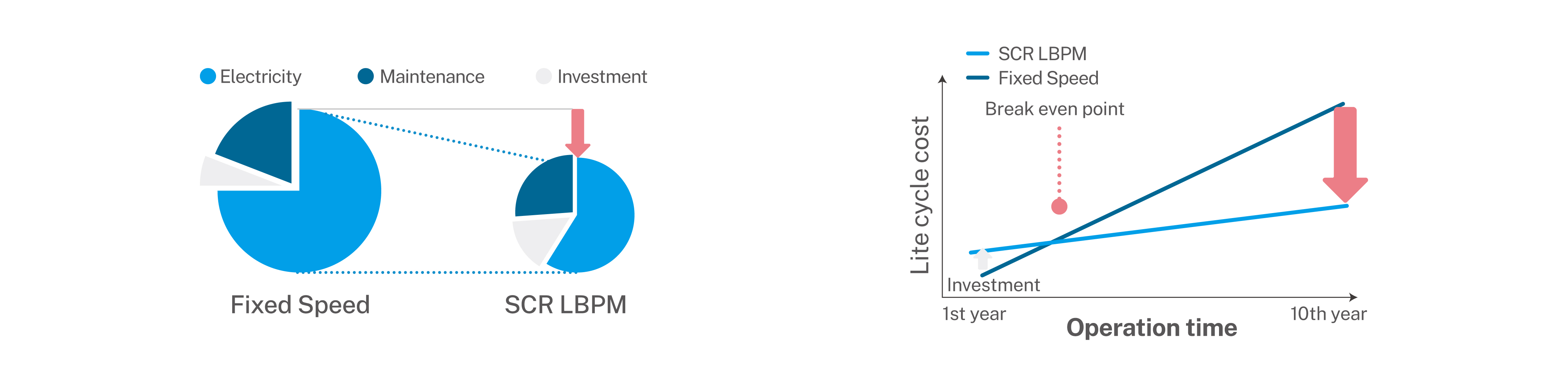

SCR low pressure compressor is option for VSD control technology with high efficiency PM motor, and it can help customer save max. Energy, As we know, what's important is not the initial cost but life cycle cost, but the electric cost .

SCR LBPM compressors may look more expensive than fixed speed models, but many customers choose them because they know importance of life cycle cost & return on investment when it comes to choosing the right compressor.

-

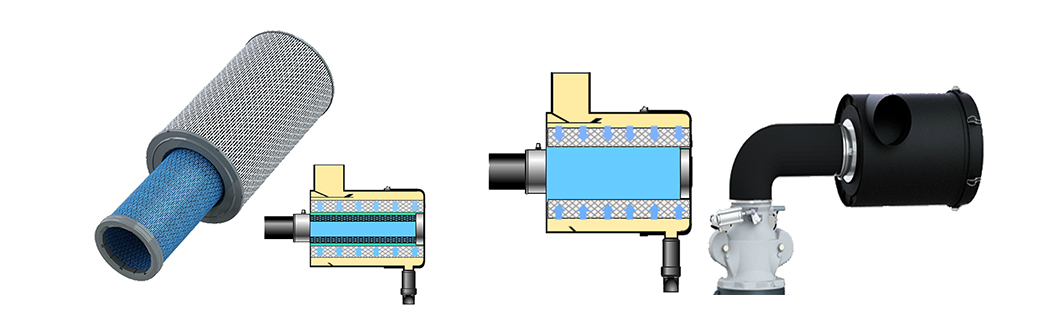

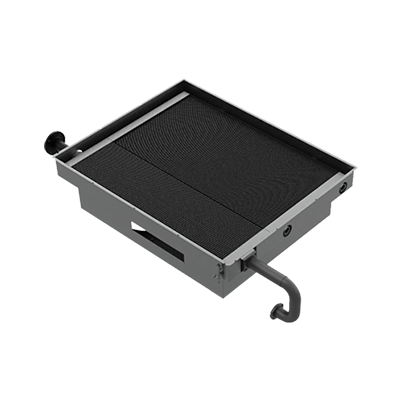

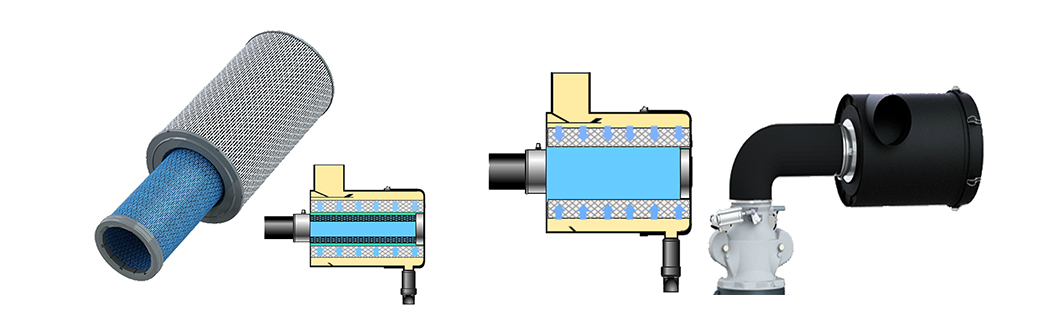

3 3.Heavy Duty Air Filter:

Double imported safety filter core,improve air filtration effect, Long service life,Large filtration area, Low suction resistance,improve air inlet efficiency. Specially for the dusty environment, like cement industry, textile industry, fibre industry, chemical industry etc.

-

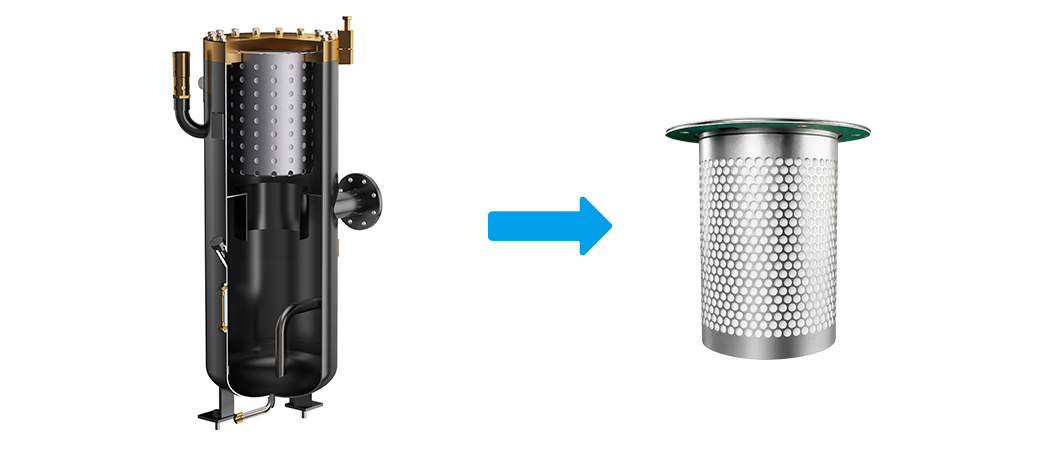

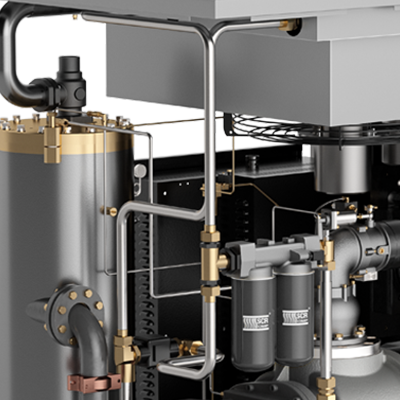

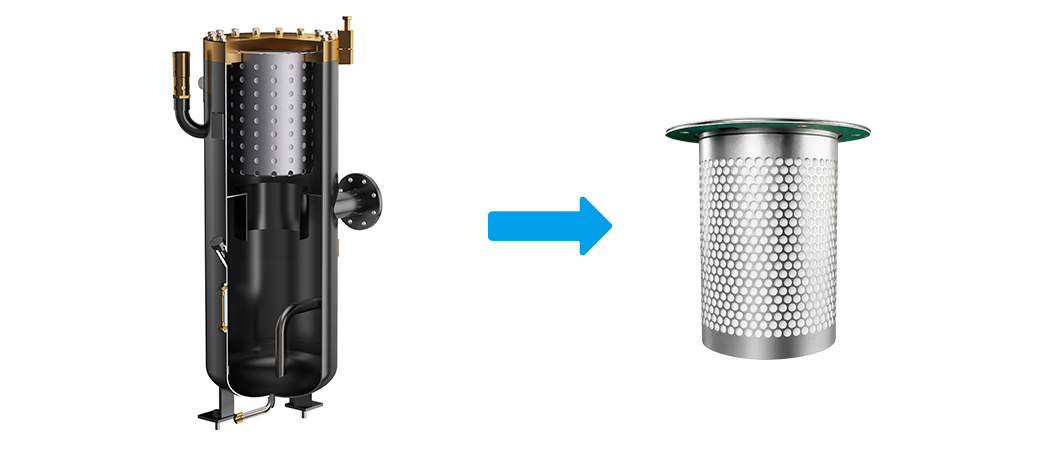

4 Oil/air tank

Big capacity oil tank, Hold internal pressure, Reduce Lubricating oil producing foam.

Tank cover design with SCR rotating shaft, Simplify oil separator core replacement.

Enlarge oil separator core size , Better separation effect, Reduce the pressure drop during operating period, Improve system efficiency.

Double oil separator core is for big size type above 340HP and above, to help better oil separation.

Oil content is less than 3PPM during 4000Hours running period.

-

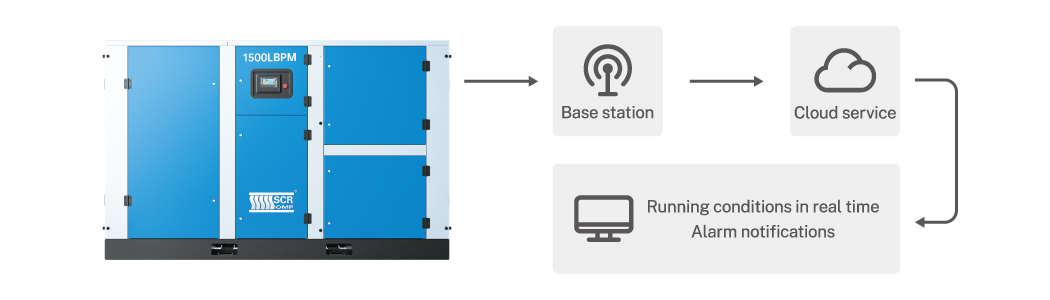

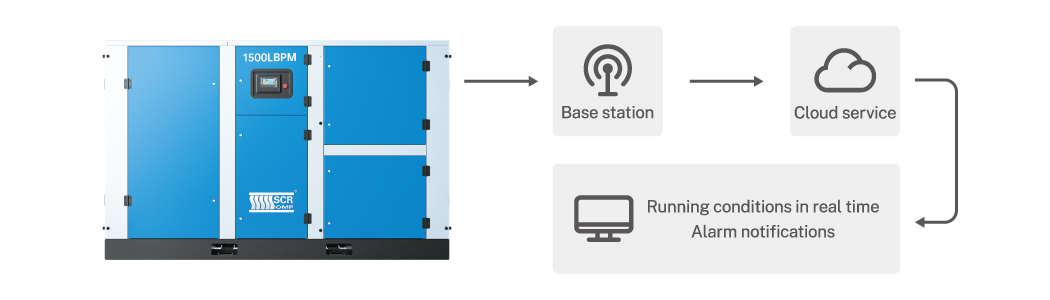

5 Option for cloud service

New air solution program with advanced IOT technology

Anytime, Anywhere

Customers can monitor the live running conditions of SCR compressors anytime, anywhere and can be accessed through a Cloud service in real time. Moreover, alarm notifications will help prevent any unplanned down time.

Reliable Security

VPN (Virtual private network) ensures the same reliable security level as the private network.

User friendly Cloud service.