How Do Rotary Screw Air Compressors Work?

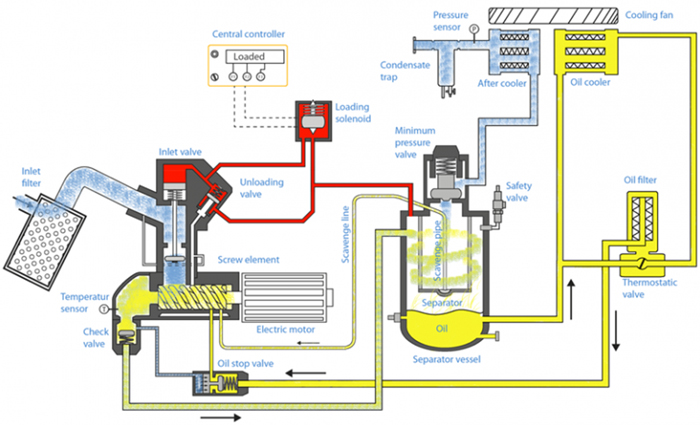

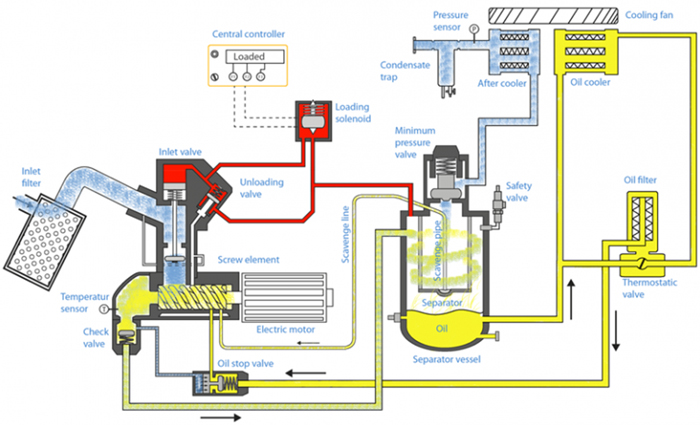

All compressors work using a mechanical element that physically reduces the volume air takes up, compressing it. In a rotary screw compressor, that mechanical component is a pair of screws. These two screws are meshed together and turn continuously. Air enters and is then compressed in the gap between the screw threads. Here’s how oil-flooded rotary screw air compressors work:

1. Air enters the compressor through the inlet valve.

2. Air then travels through the pressure control line and into the regulator valve. This process sets the air pressure for the system.

3. Both oil and air enter the compressor, where they combine into a mist. Air travels the length of the matching rotary screws and becomes compressed.

4. After exiting the compressor, the air and oil mist enters the primary oil separator tank. The tank uses centrifugal force to make the oil molecules come together, forming droplets that fall to the bottom of the tank. The oil can then be recycled into the air compressor for the next batch of air.

5. The air then enters a secondary separation filter, which further purifies the air and removes more of the oil.

6. The oil-free air then exits the system, into a reserve tank or the connected air tools or machinery.

7. The oil travels from the separator tank to an oil cooler. Next, it goes through a filter that removes any debris and is then returned to the air compressor.

SCR focuses on the research and development, manufacturing, sales and service of industrial air compressor. SCR has 16 years experience and work with Iwata to create a new technology and quality system .China SCR screw compressor is more efficient, and energy-saving.

Air Tank

Air Tank Low pressure Permannent Magnetic VSD screw air c

Low pressure Permannent Magnetic VSD screw air c low pressure Two stages screw compressor LH/LHPM

low pressure Two stages screw compressor LH/LHPM  High speed direct drive twin screw oil-free air c

High speed direct drive twin screw oil-free air c Permanent Magnetic VSD Screw air compressor APM s

Permanent Magnetic VSD Screw air compressor APM s Permanent Magnetic VSD Screw air compressor EPM/E

Permanent Magnetic VSD Screw air compressor EPM/E Oil Free Scroll Compressor XA series

Oil Free Scroll Compressor XA series Permanent Magnetic VSD Screw air compressor PM se

Permanent Magnetic VSD Screw air compressor PM se