What is TUV?

TüV (Technischer überwachungs-Verein) means Technical Inspection Association in English.

The TüV mark is a safety certification mark customized by German TüV for component products, and is widely accepted in Germany and Europe. At the same time, companies can apply for CB certificates in combination when applying for the TüV mark, thereby obtaining certificates from other countries through conversion. Moreover, after the products have passed the certification, TüV of Germany will come forward to inquire about qualified component suppliers' rectifier manufacturers to recommend these products; in the process of complete machine certification, all components that have obtained the TüV mark are exempt from inspection.T?V S?D is an international certification organization that provides professional management system certification services. T?V S?D has mastered professional international management system audit and certification skills, and conducts testing and certification on quality, environment, energy, safety, risk, health, education, business continuity, and social responsibility. The fields involved include automotive, railway, aviation, mechanical engineering, information technology, banking, finance and health services

TUV logo – Image Credit

The full name of T?V is "Technische ?berwachungs Vereine", which is the abbreviation of "Technical Supervision Association" in German. It does not carry out actual business itself.

At present, five companies are authorized to operate TUV business in Germany according to the region[1], specifically TUV RH (Rhine), TUV NORD (North Germany), TUVPS (South Germany), RWTUV (Hand), TUV Saarland (Saar) [2] . Since September 1, 2004, TUVNORD and RWTUV merged into the new TUV North Germany.

TUV Rheinland, headquartered in Germany, is an international certification body with branches in more than 30 countries around the world. Its organizational form is similar to that of the United States. It is also in charge of various government departments in accordance with commodity categories, and conducts inspection, supervision and management according to relevant laws or government approvals. The German Technical Inspection Agency Network (TUV) is officially recognized and is responsible for the quality of goods in the market. As a prestigious international certification body, the company has a history of more than 130 years in the field of product inspection and certification, forming a complete and rigorous inspection theory and method, and is committed to becoming a leader in providing safety and quality certification services. With more than 80 branches and more than 7,400 professionals in the world, we provide comprehensive safety and quality services to customers all over the world. It is the international authority to independently test product safety and quality and management system

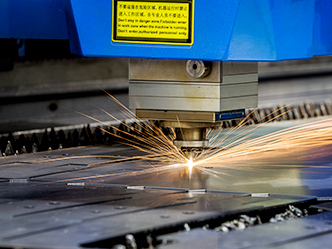

Electrical Safety Testing

The TUV testing laboratories are equipped to carry out different tests on a wide range of electrical and electronic equipment. This enables them to cater to manufacturers of telecommunication, information technology, laboratory equipment, white and brown goods, and much more.

Testing electrical equipment is one way of ensuring that they comply with relevant standards, regulations, and directives. The testing, which may be partial or full, enables the product manufacturers to meet safety standards and customer requirements, hence preventing faulty or unsafe equipment from entering the markets.

By testing and certifying that their products meet applicable safety standards, the manufacturers show that they have confidence in their products while sending a message on their commitment to user safety. When equipment is tested before being released into the market, it saves the manufacturer from expensive product recalls as well as numerous potential litigations.

TUV provides services such as testing, inspections, training, certification, and other services that help manufacturers build and maintain consistent quality. They use the current directives and regulatory requirements to carry out their testing throughout the product lifecycle, hence allowing manufacturers to take corrective measures along the way.

Some of the areas tested include:

General Construction of the product

Equipment assembly

Mechanical, Electrical, and Fire enclosure

Physical requirements such as stability

Power supply and wiring connections

Protective earth and grounding

Label Requirements

Marking

Environmental testing

Electromagnetic interference testing

Product performance and reliability testing

These tests are carried out in their laboratory spread across several cities in the world. However, for plant equipment and other products that can only be tested in the field, TUV carries out the required tests at the customer’s site where the equipment is installed.

TUV ensures that customers who get certified products get efficient equipment that is safe and capable of serving them well. Manufacturers with certified products that meet the global standards have better chances over competitors whose products are uncertified or that do not meet the recommended safety and operational standards.

High speed direct drive twin screw oil-free air c

High speed direct drive twin screw oil-free air c Air Tank

Air Tank Low pressure Permannent Magnetic VSD screw air c

Low pressure Permannent Magnetic VSD screw air c low pressure Two stages screw compressor LH/LHPM

low pressure Two stages screw compressor LH/LHPM  Permanent Magnetic VSD Screw air compressor APM s

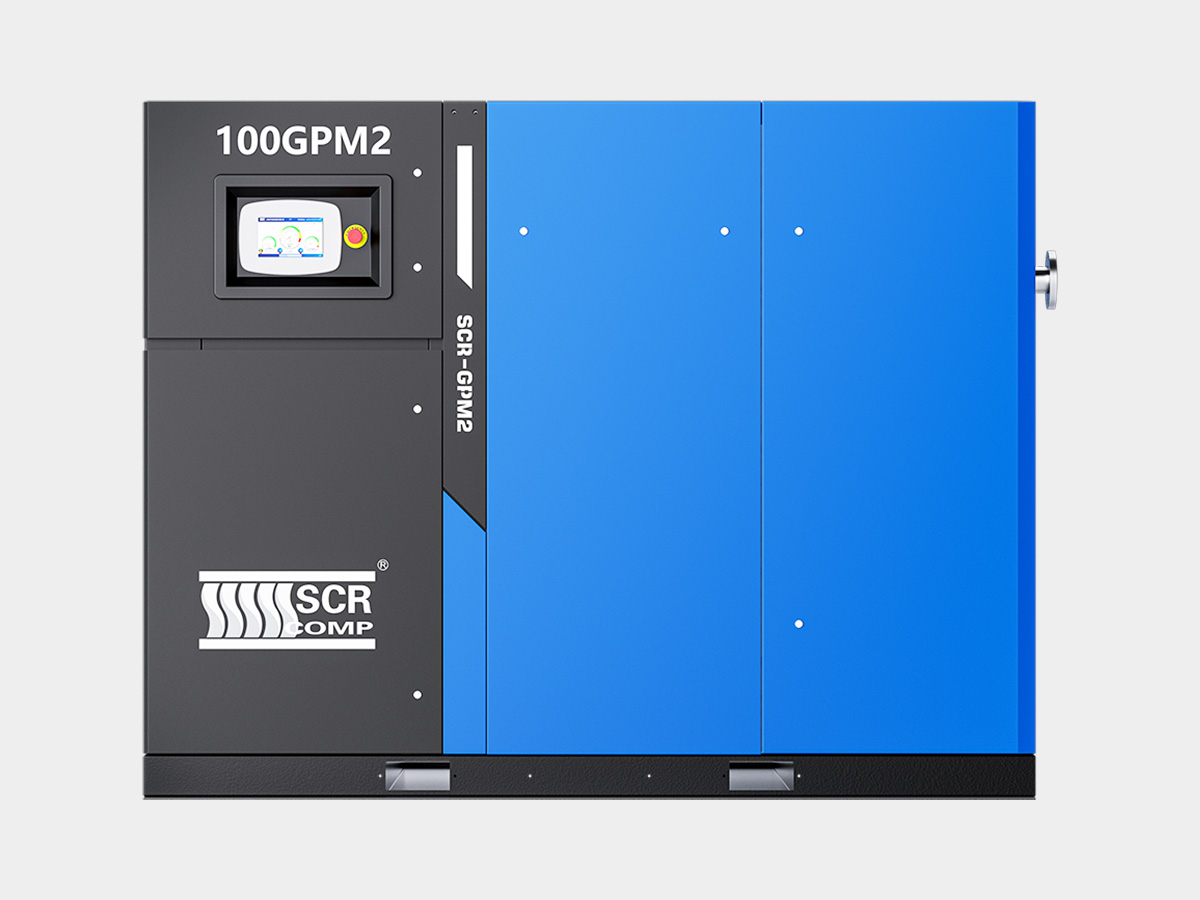

Permanent Magnetic VSD Screw air compressor APM s Permanent Magnetic VSD Screw air compressor EPM/E

Permanent Magnetic VSD Screw air compressor EPM/E Oil Free Scroll Compressor XA series

Oil Free Scroll Compressor XA series Permanent Magnetic VSD Screw air compressor PM se

Permanent Magnetic VSD Screw air compressor PM se