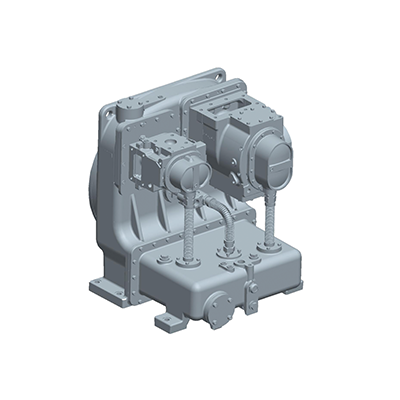

-

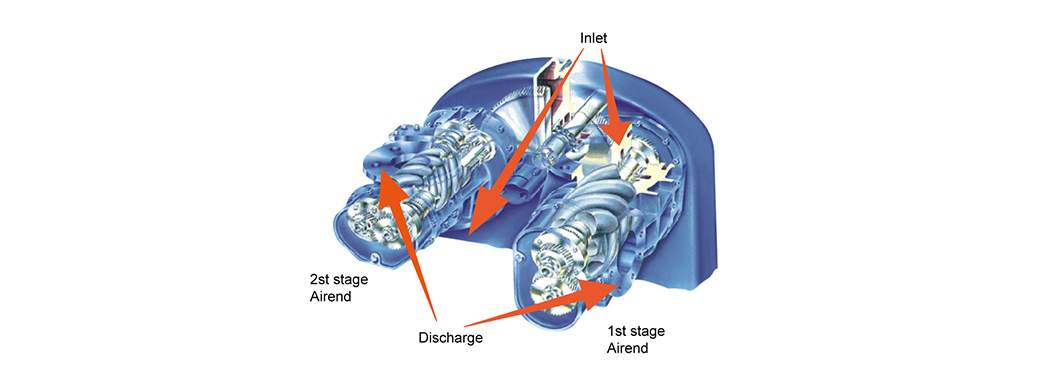

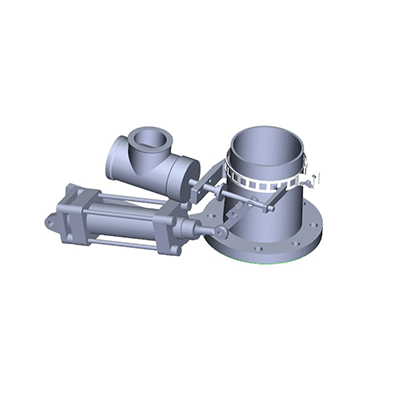

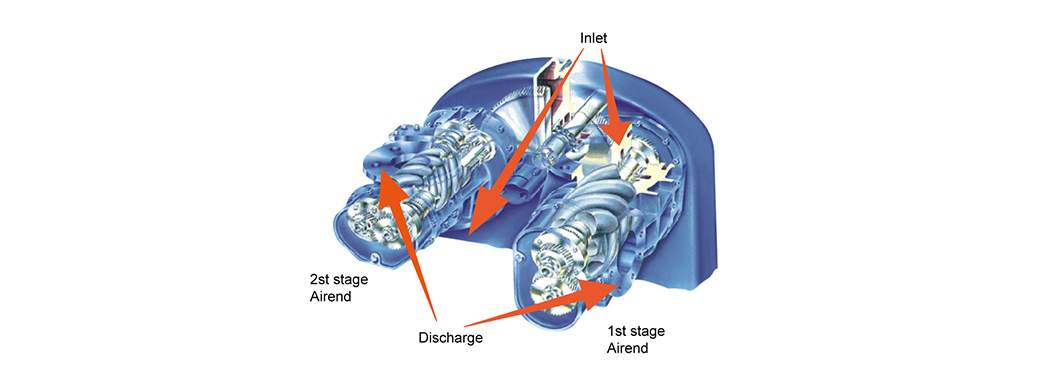

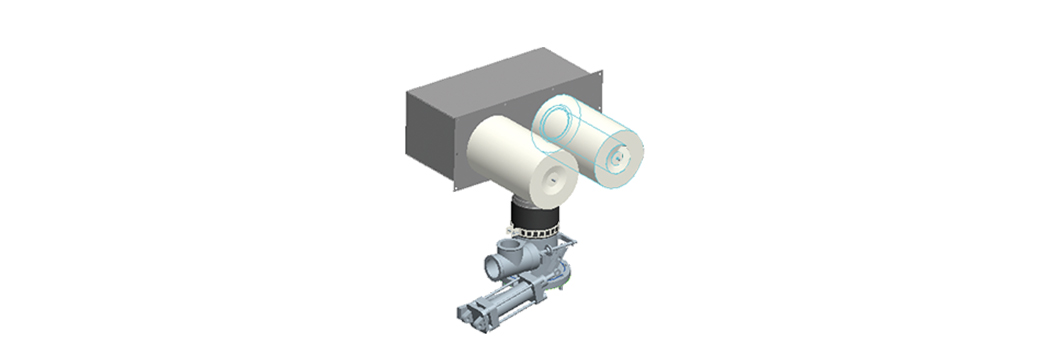

1 Germany GHH-RAND Oil Free Airend.

Two Stage Dry Compression, The first-grade rotor is E35 steel. The second-grade is stainless steel, it’s 100% oil free during compression process.

Ultra Coating at rotor surface, make sure the tolerance of airend.

Stainless steel hermetic seal and labyrinth oil seal. Double protection method to guarantee 100% oil-free compressed air.

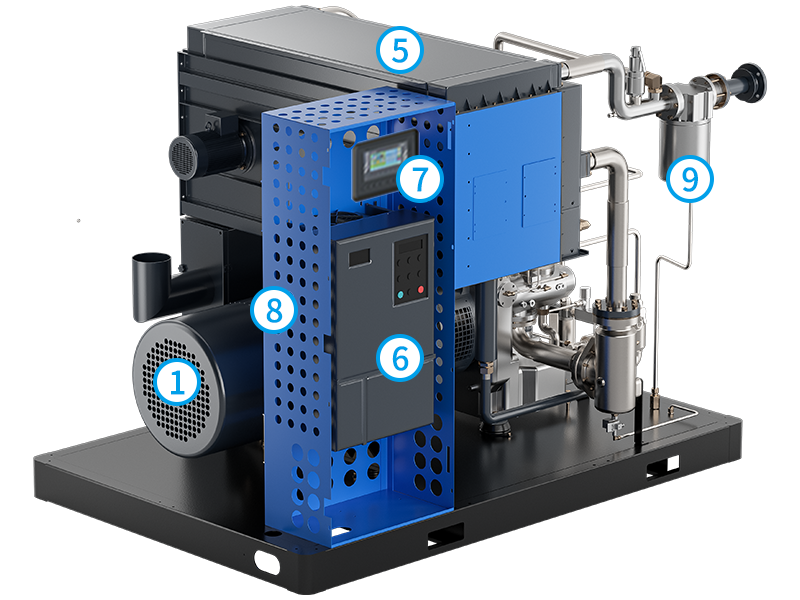

-

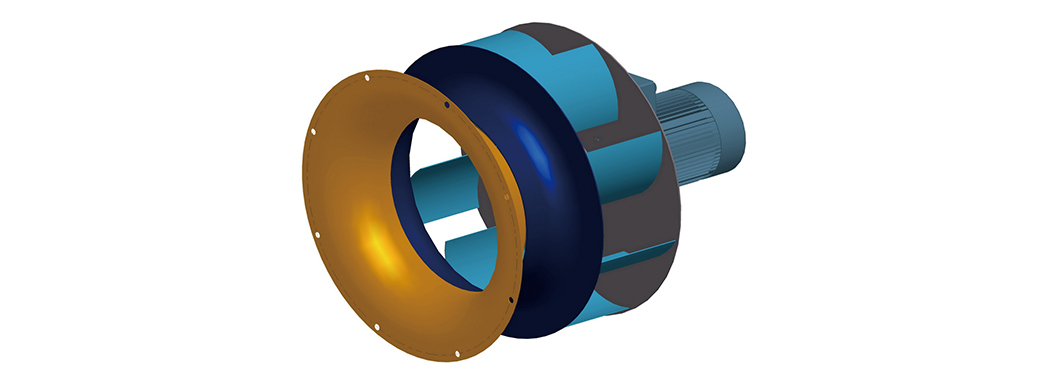

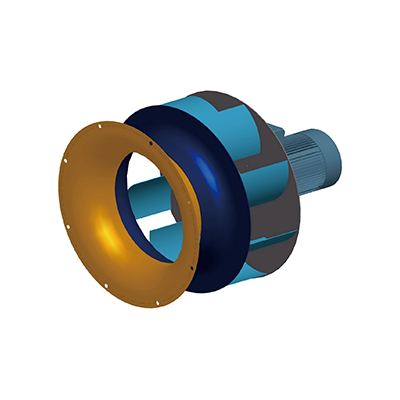

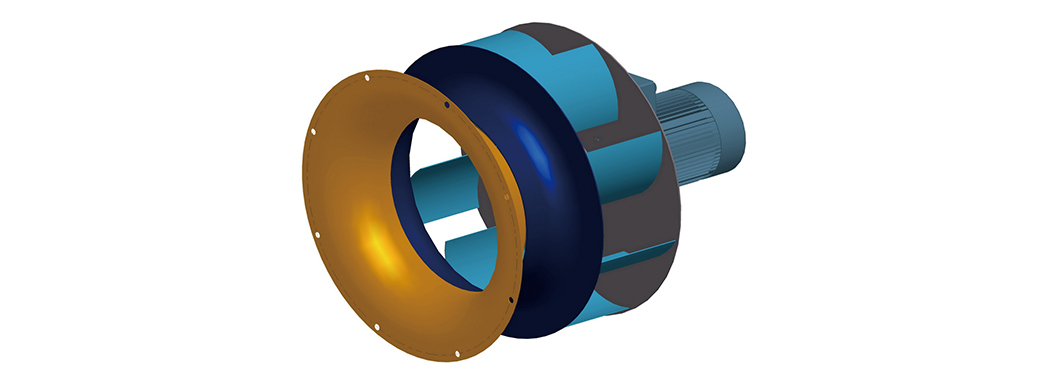

2 Centrifugal fan

As for air cooling type, it take use of centrifugal fan, which has low noise, high wind pressure features, more environment friendly.

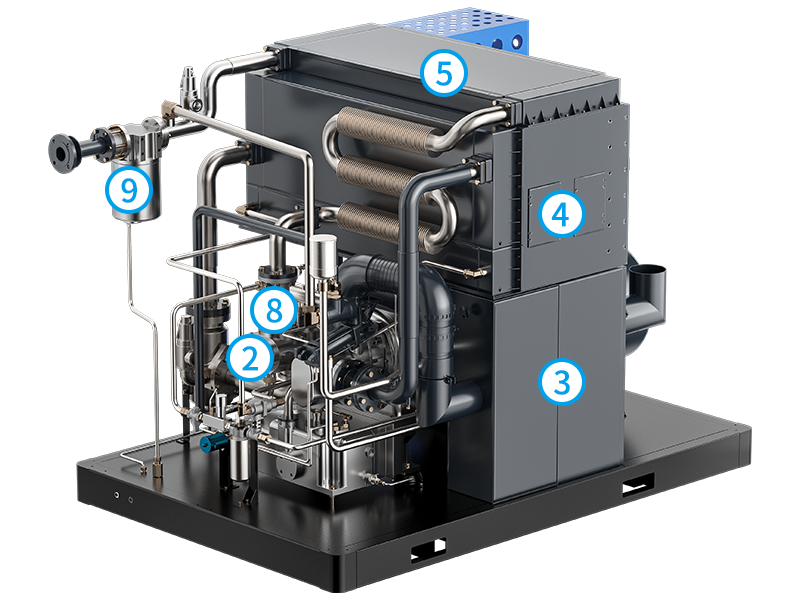

-

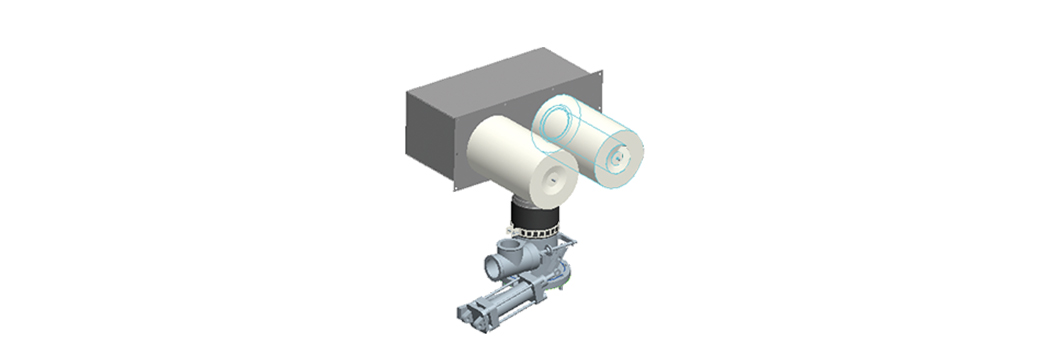

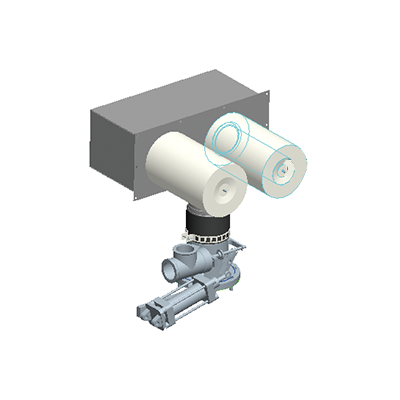

3 Air inlet system

Independent inlet silencer box, Ensure the air filter inlet temperature equal to the ambient temperature, which will help reduce the power consumption. At the same time, it isolate the noise inside of this box, so help reduce the noise level a lot.

-

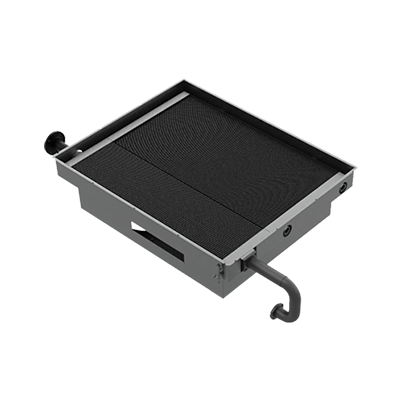

4 SCR9000 Touch screen controller

1.7” touch screen PLC, easy for operation.

2.Full features protection, including over temp. Protection, over pressure protection, motor overload, phase unbalance etc. more than 13itmes protection.

3.Support intelligent control, such as running schedule, auto startup after power failure.

4.Support Modbus RTU, and can realize remote monitoring.

-

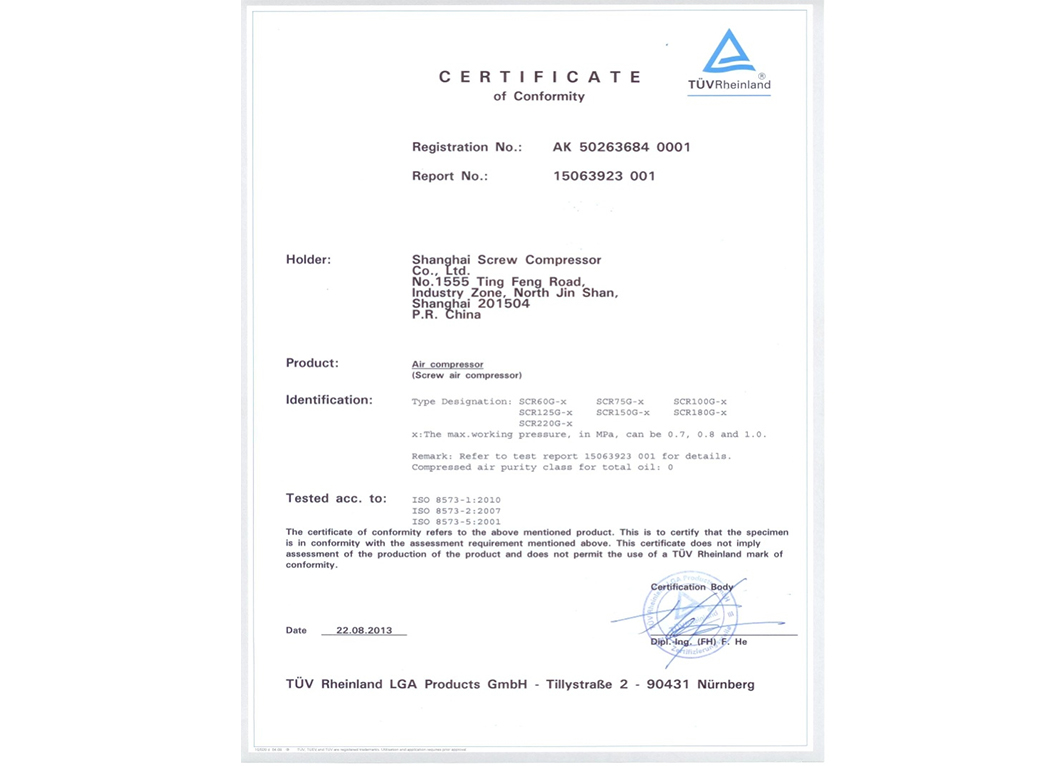

5 Class 0 certificate

Class 0 oil free certificate from TUV.