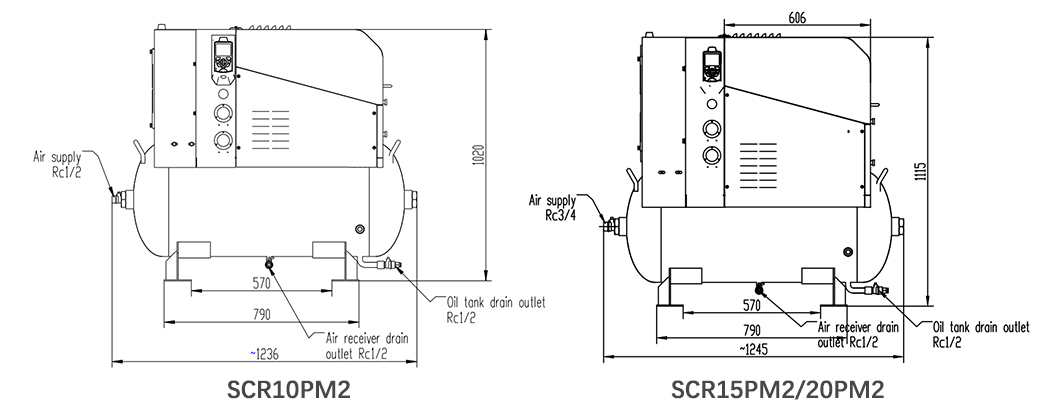

-

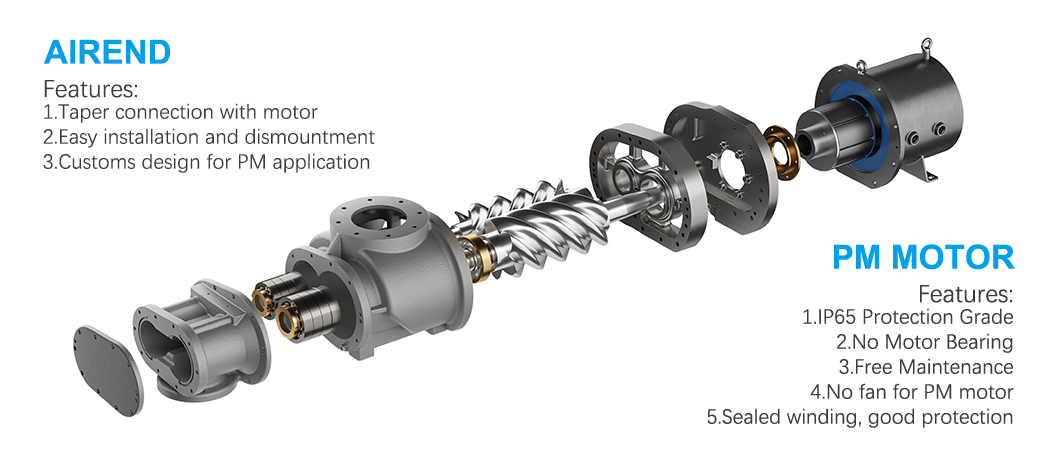

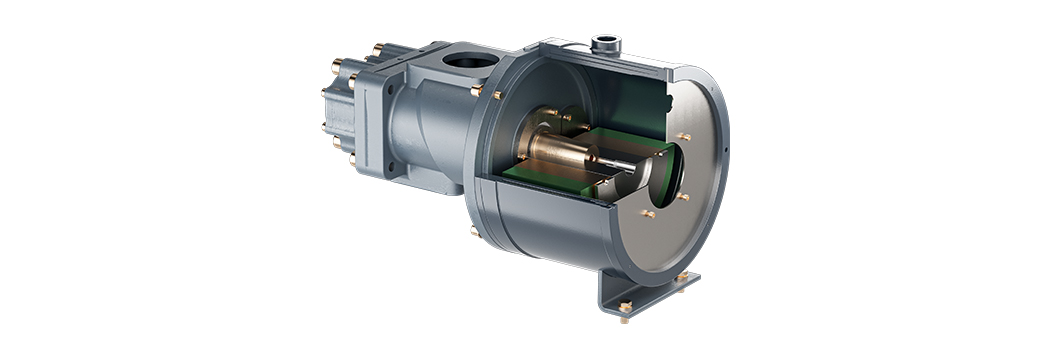

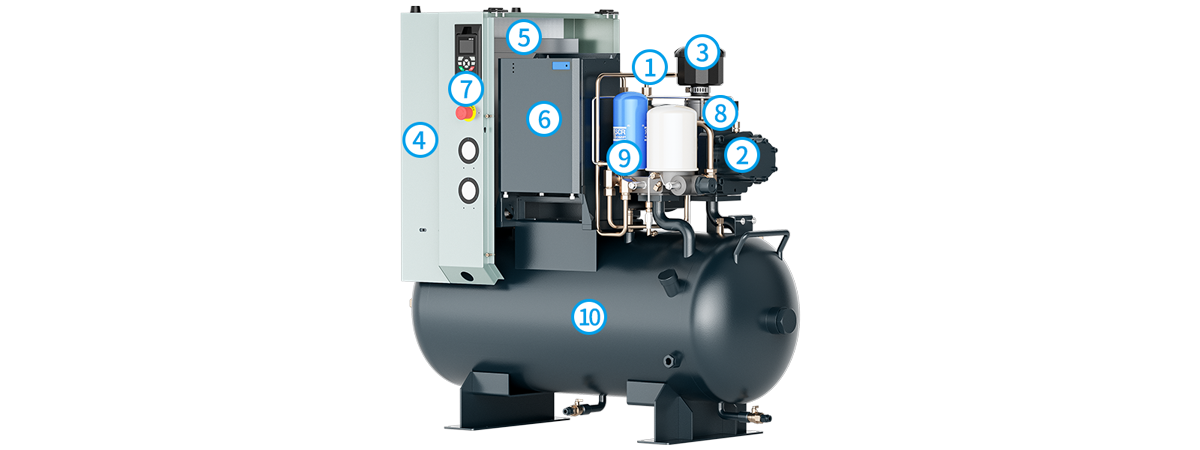

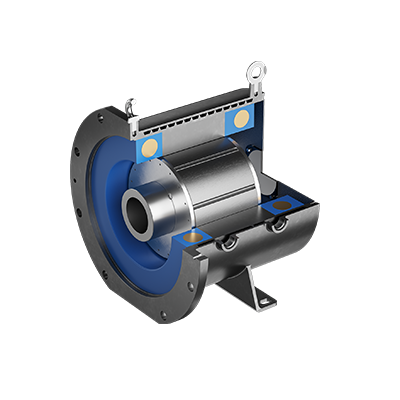

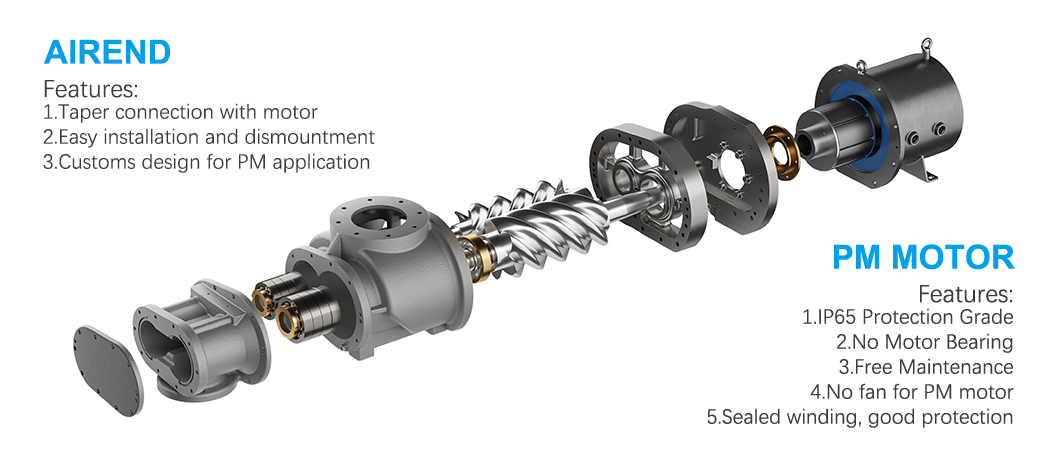

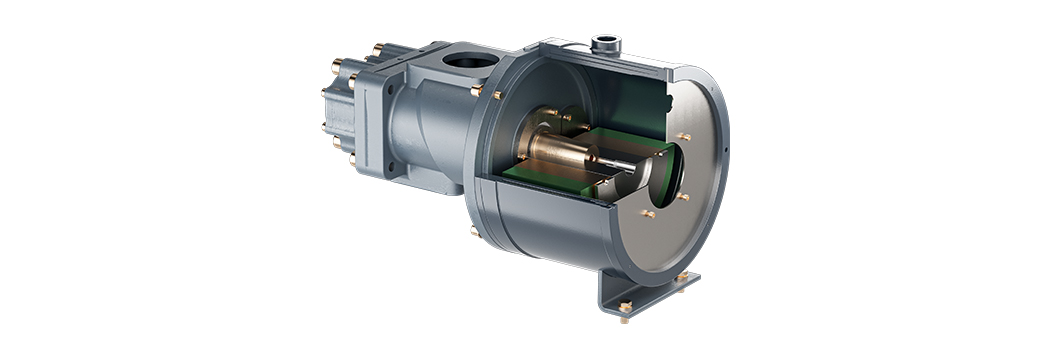

1 Airend and PM Motor

-

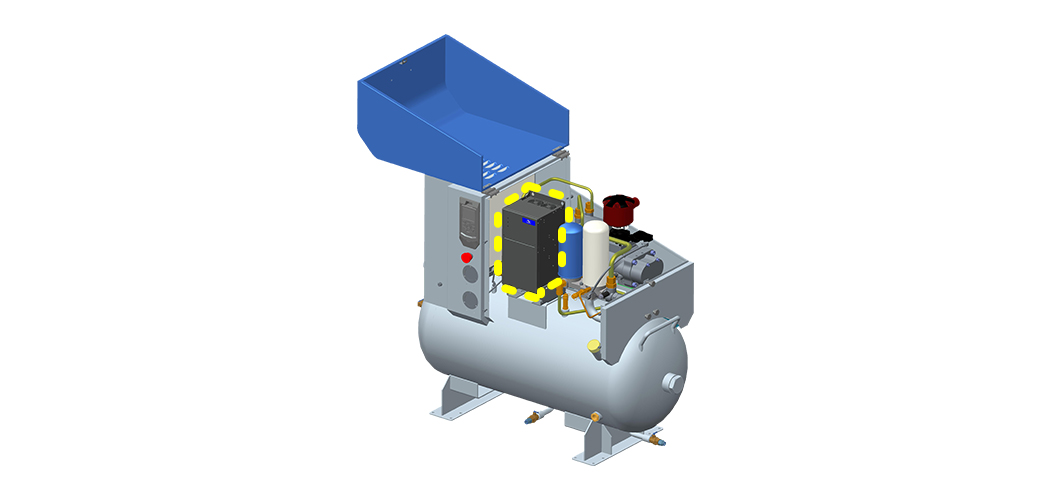

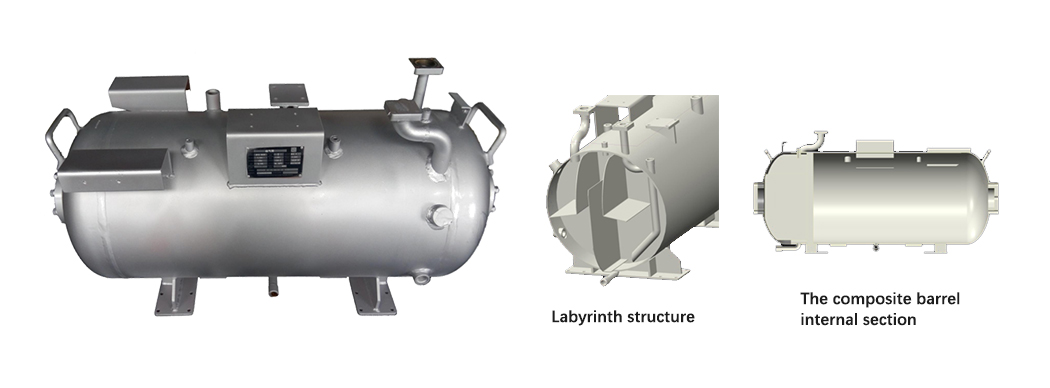

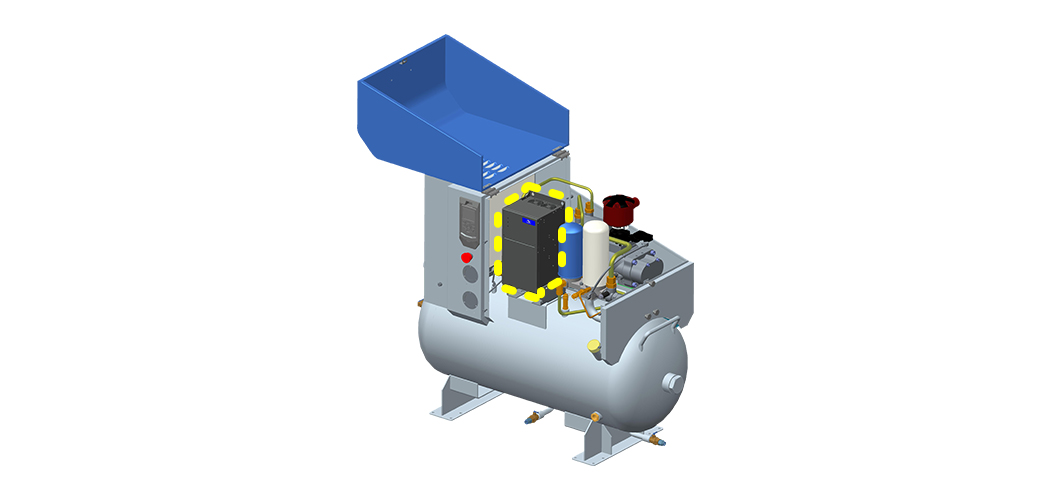

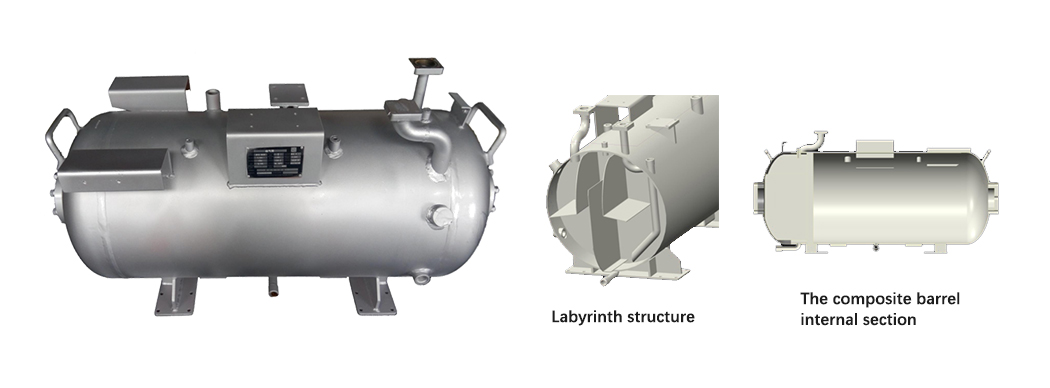

2 INSIDE STRUCTURE

1.Integrated all in one keypad control.

2.Easy operation.

3.Intelligent function, like remote on/off, running schedule, auto startup function.

4.VSD start up, reduce impact to customer grid network.

-

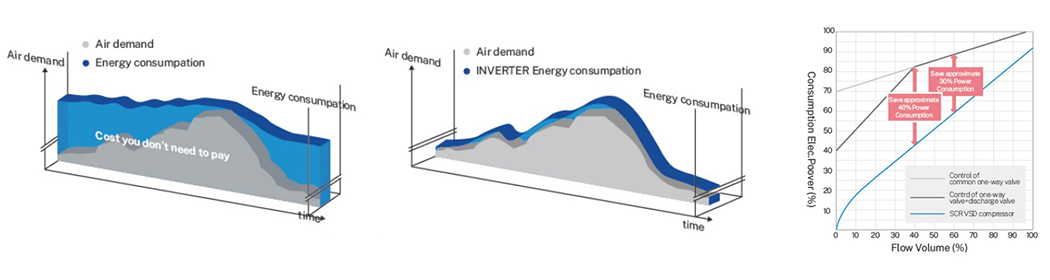

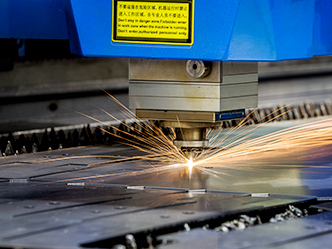

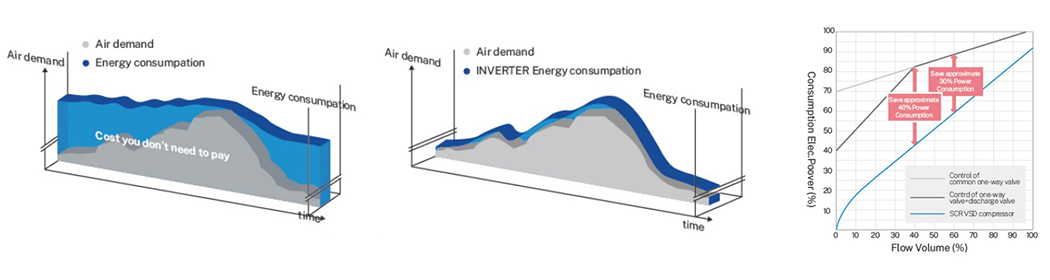

3 What you pay should be only for what you use

SCR compressor can adjust compressor's rotating speed depends on the demand of factory load which changes from moment to moment by own developed algorithm. Thus, it can provide exact volume and pressure what customer needs and achieve maximum energy saving.

Achieve an energy-saving effect under any load operation through wide-range inverter control, wide-range control, and e-STOP function.

-

4 Special morse connection

PM motor rotor is directly mounted on the airend shaft, No gears or belts, no coupling, Zero transmission loss, Easy for installation, No need to make adjustment, Better protection for inner parts of PM motor. There’s no bearing for the PM motor, so motor is 100% free maintenance, Reduce maintenance cost.

-

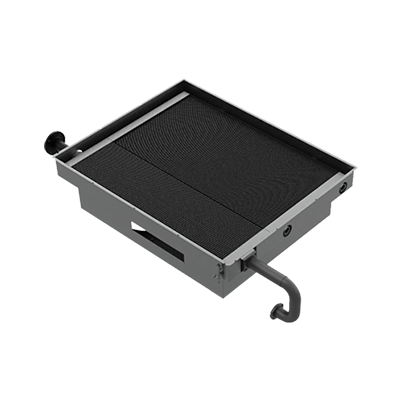

5 INTEGRATED TANK

1.Integrated tank with labyrinth structure, help reduce oil content, and better oil air separation efficiency.

The oil content is less than 3 PPM.

2.Save the space structure, make the whole layout more compact and reasonable.

3.SCR unique patent with CE certification.

-

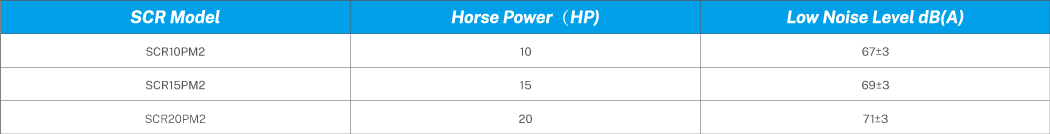

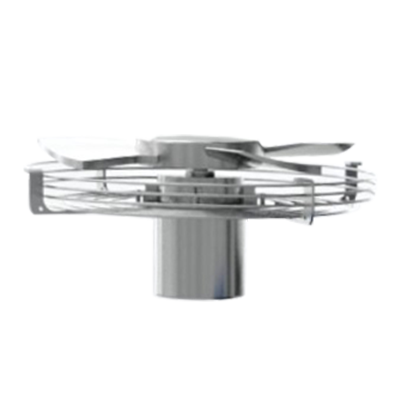

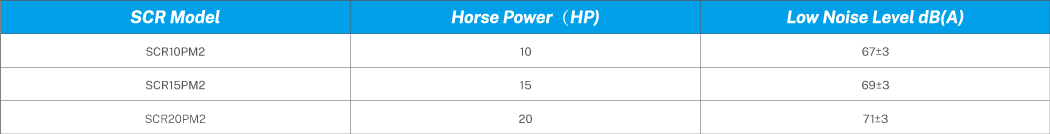

6 LOW NOISE

Oil-cooled motor reduce noise level a lot.

Low airend RPM, direct connection, less noise level.

Design for on-site operation.

-

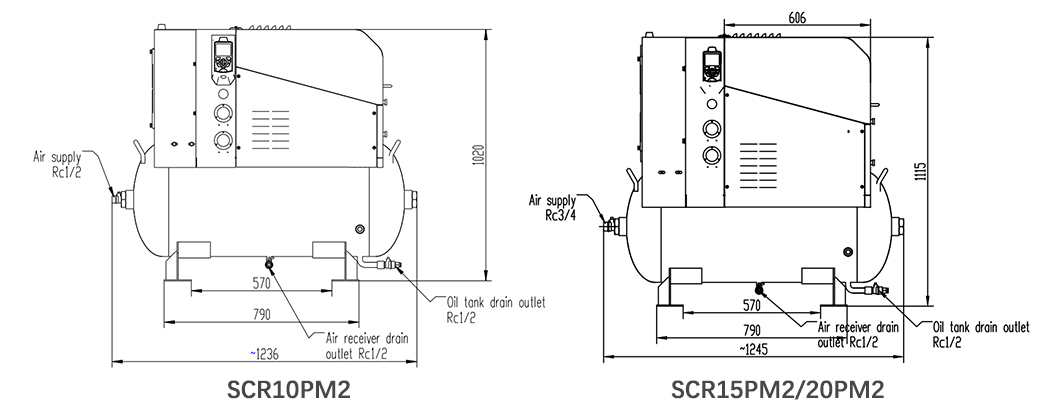

7 Compact Structure