How to choose air compressor suitable for glass industry?

How to choose air compressor suitable for the glass industry?

The emergence and use of glass have a history of more than four thousand years in human life. Nowadays, glass is widely used in daily architectural use, art, medical treatment, chemistry, electronics, instrumentation, nuclear engineering, and other fields. Glass bottles are closely related to our everyday life.

Glass bottle production process & compressed air application

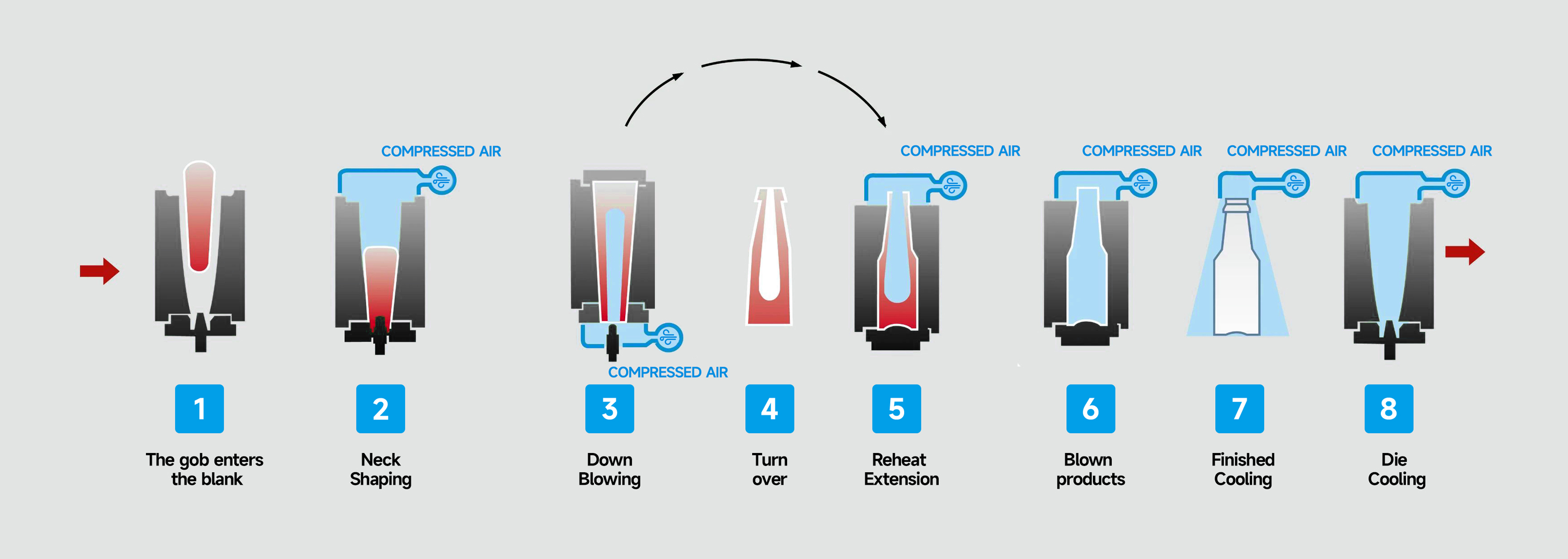

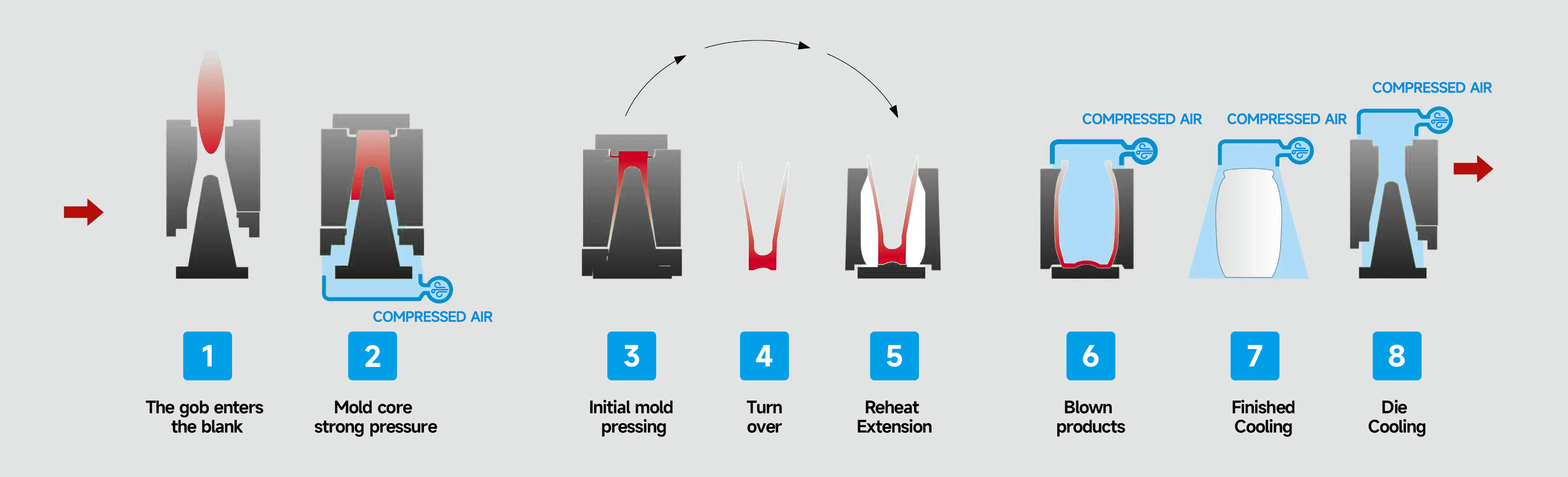

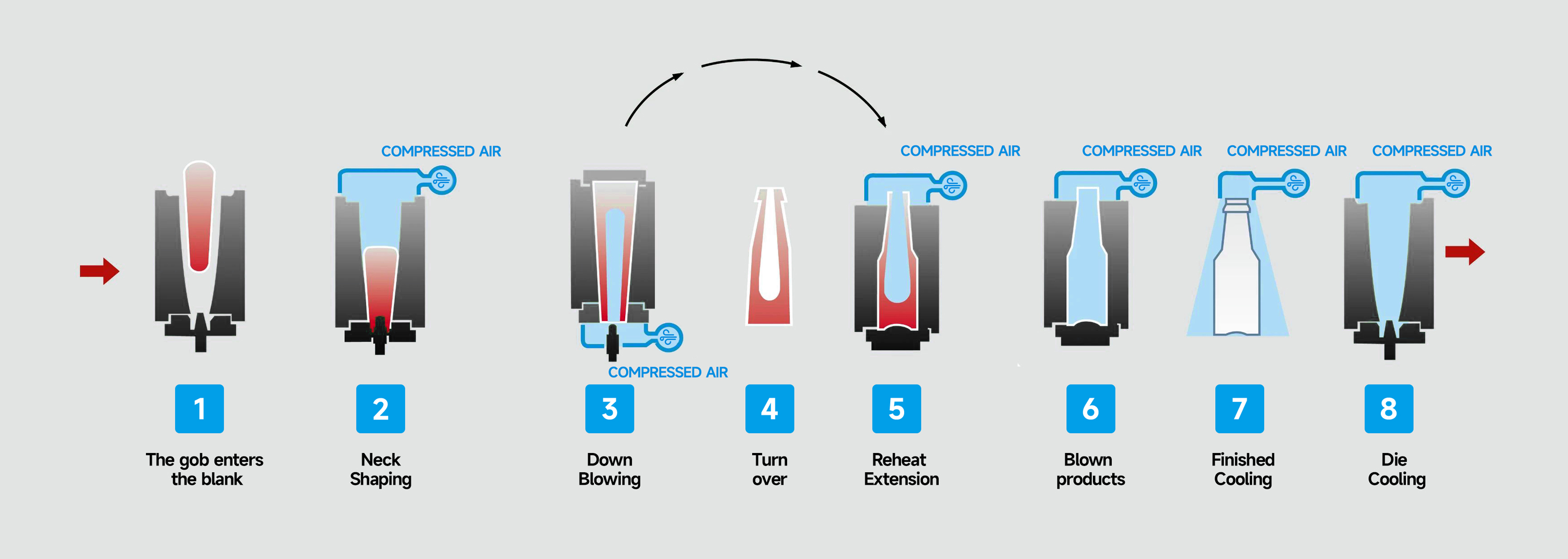

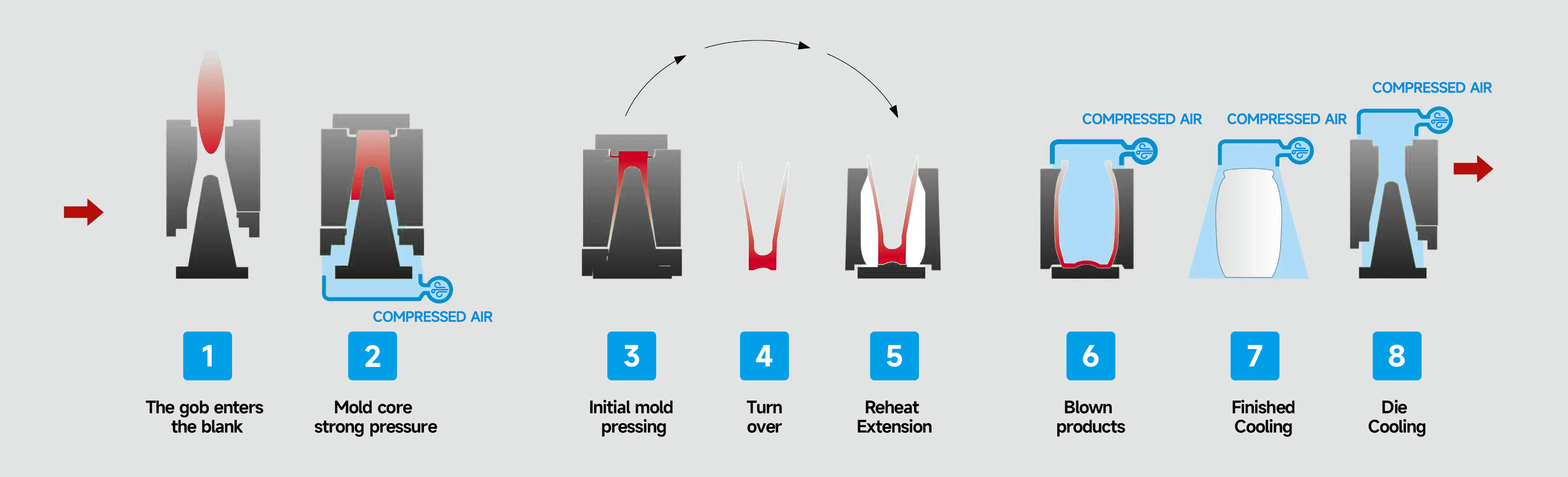

In the "forming" process, compressed air is injected into the molten liquid glass, and the pressure of the compressed air is used to extend the liquid glass into bottles of different shapes. At present, the mainstream manufacturing equipment for glass bottle forming in the market is a determinant bottle-making machine, which has two production methods: the blow-blow method and the pressure-blow method.

The blow-and-blow method is suitable for blowing bottles with narrow mouths.

The process is

Glass bottle manufacturing process——blow-and-blow method

The pressure blow method is suitable for blowing bottles with large necks

The process is as follows:

Glass bottle manufacturing process——pressure blow method

Compressed air requirements for bottle-making machines

Bottle-making machine is mainly driven by compressed air applied to most of the process points and can be divided into two types according to the purpose.

Operating air

Require:

Compressed air pressure: 2 bar

Mainly used: System process gas

Blown air

Require:

Compressed air pressure: 3 bar

Mainly used:

Various blowing processes, such as puffing, internal cooling forward blowing, reverse blowing, core cooling, core rising, etc.

Compressed air quality requirements

The production process of the glass bottle-making machine is very precise. Even a small amount of water, impurities, and oil mist mixed into it will affect the quality of the glass bottle. Therefore, the compressed air used for the bottle-making machine must be of high quality without oil, water, and dust.

SCR Compressor Bottle blowing industry solutions

——OIL-FREE VSD Magnetic Levitation Centrifugal Compressor

OIL-FREE VSD Magnetic Levitation Centrifugal Compressor

The magnetic levitation centrifugal air compressor adopts advanced magnetic levitation bearing technology, which saves the gearbox and oily bearing necessary for traditional equipment, so it achieves no lubricating oil and no mechanical maintenance. Provide users with pure compressed air, effectively reduce users' maintenance costs, improve system operation stability, and meet customers' various production needs.

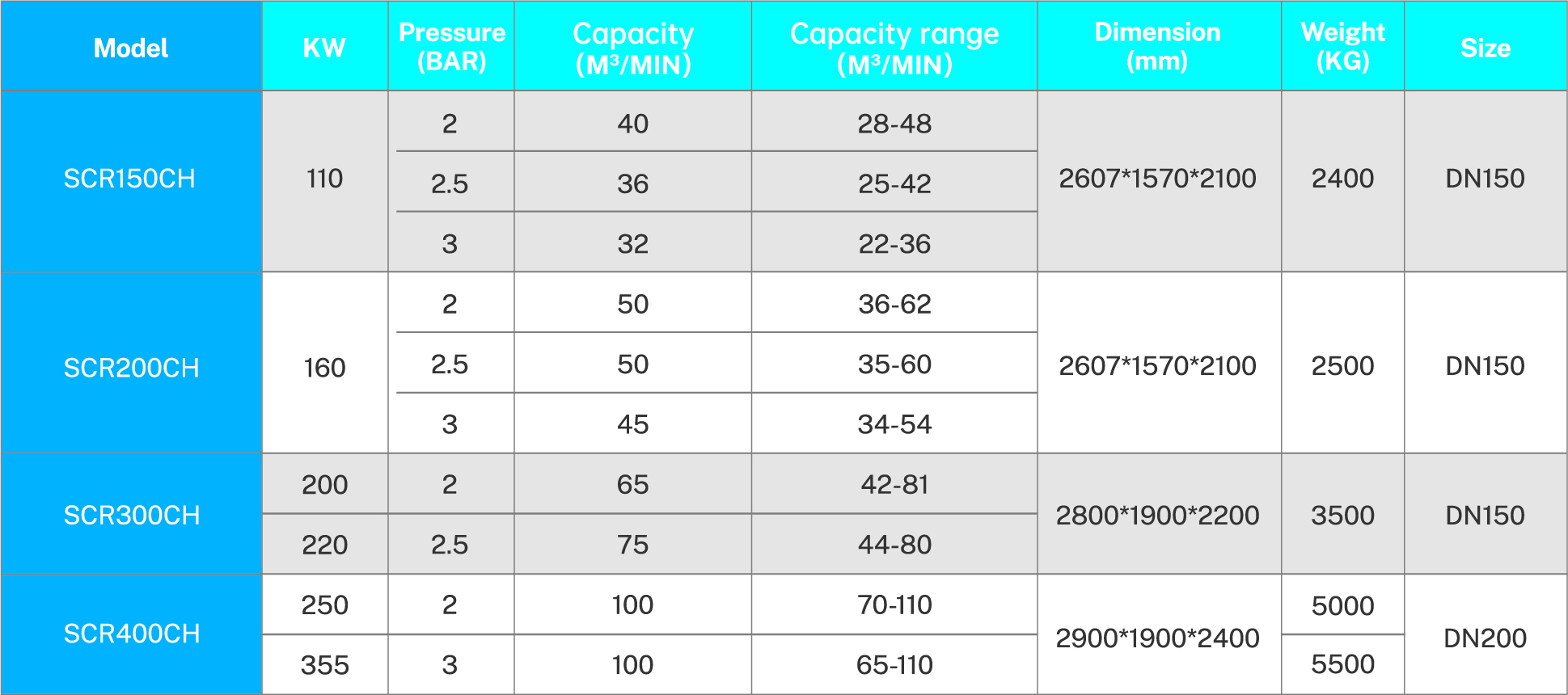

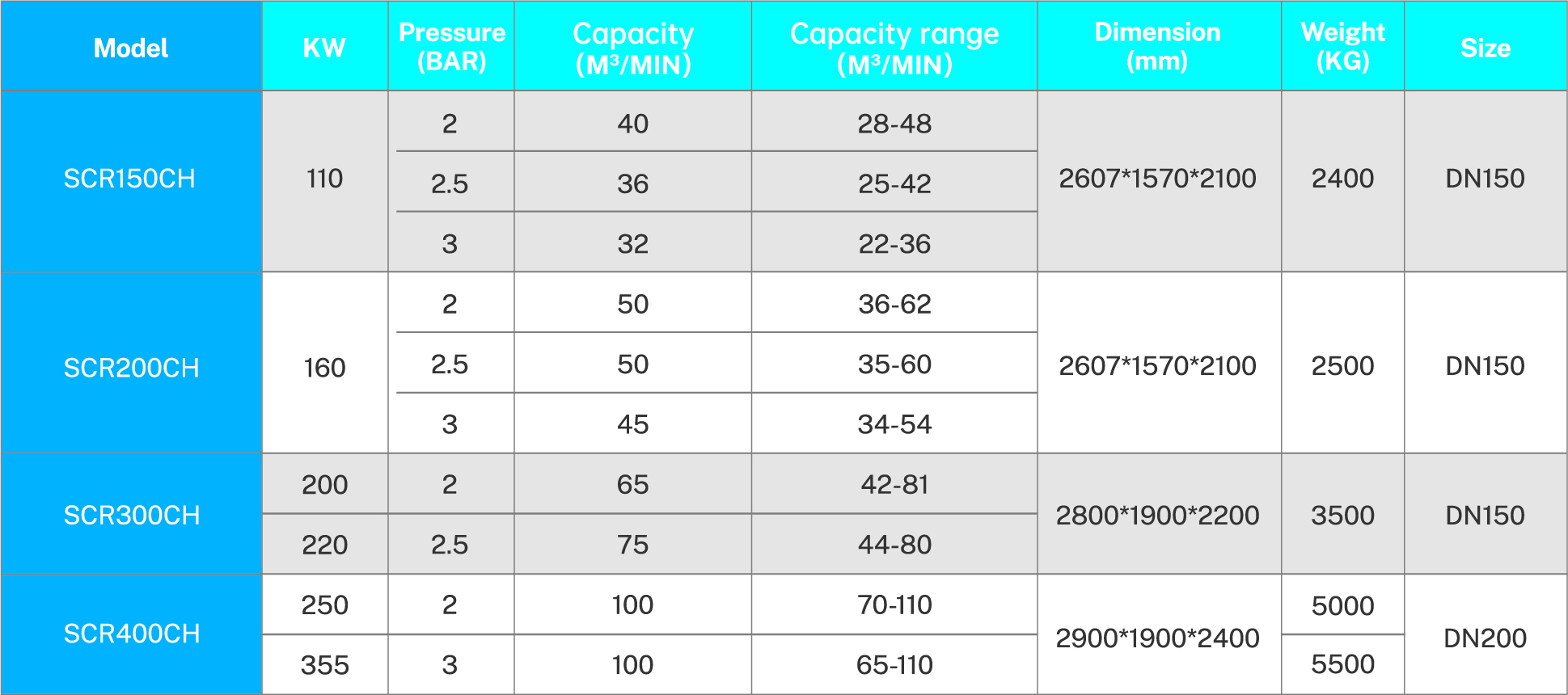

110 - 355 KW OIL-FREE VSD Magnetic Levitation Centrifugal Compressor Parameter

Glass blowing 2-3bar

Product Case——Glass industry

CASE 1

Product Mame: OIL-FREE VSD Magnetic Levitation Centrifugal Compressor Parameter

Model: SCR300CH

CASE 2

Product Mame: OIL-FREE VSD Magnetic Levitation Centrifugal Compressor Parameter

Model: SCR300CH

High speed direct drive twin screw oil-free air c

High speed direct drive twin screw oil-free air c Air Tank

Air Tank Low pressure Permannent Magnetic VSD screw air c

Low pressure Permannent Magnetic VSD screw air c low pressure Two stages screw compressor LH/LHPM

low pressure Two stages screw compressor LH/LHPM  Permanent Magnetic VSD Screw air compressor APM s

Permanent Magnetic VSD Screw air compressor APM s Permanent Magnetic VSD Screw air compressor EPM/E

Permanent Magnetic VSD Screw air compressor EPM/E Oil Free Scroll Compressor XA series

Oil Free Scroll Compressor XA series Permanent Magnetic VSD Screw air compressor PM se

Permanent Magnetic VSD Screw air compressor PM se