-

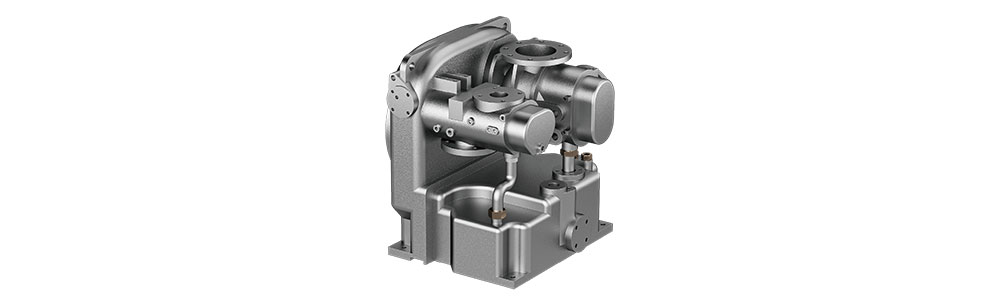

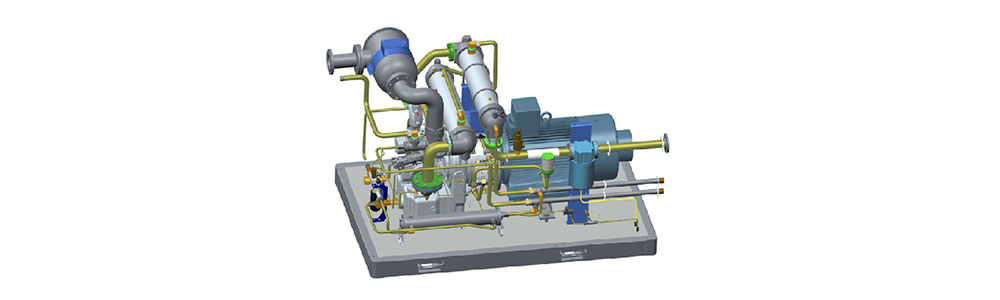

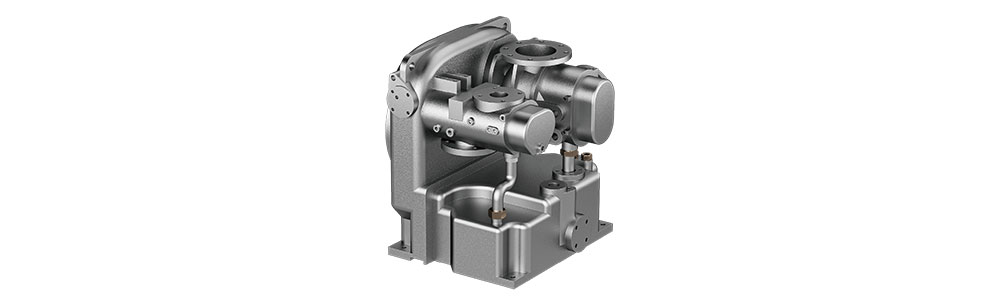

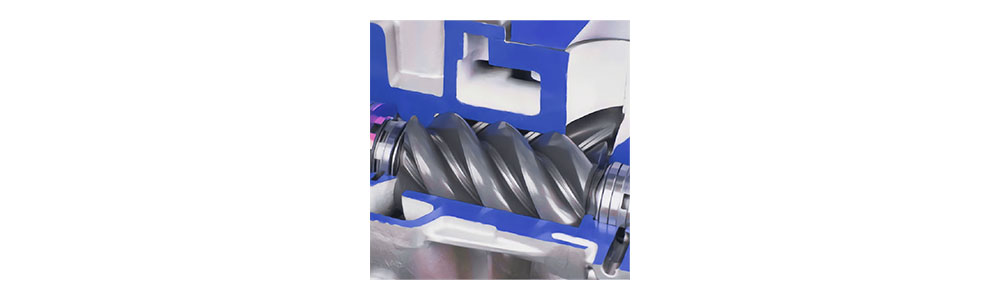

1 Oil-free screw head

Using German GHH-rand dry oil-free airend, excellent oil-free airend technology, compressed nitrogen is 100% oil-free. Two-stage compression is efficient and stable.

-

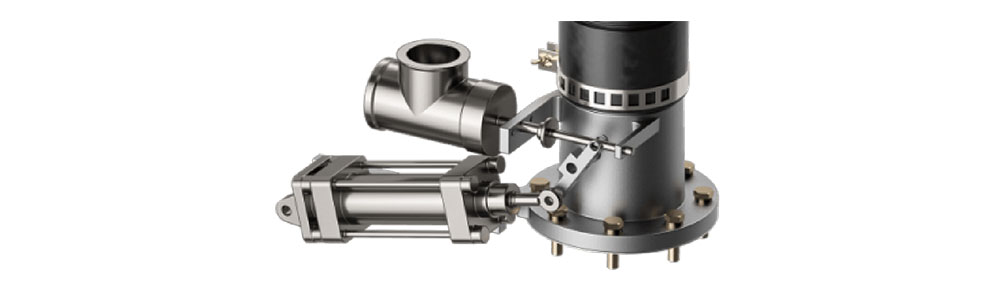

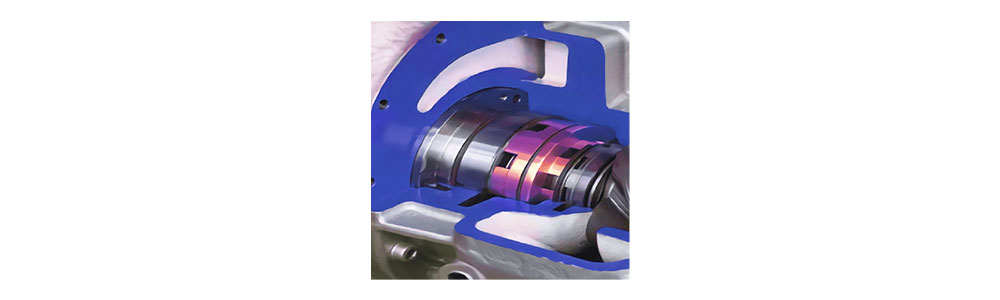

2 double seal

Stainless steel air seal and labyrinth oil seal, double protection measures to ensure purity and pollution-free nitrogen.

-

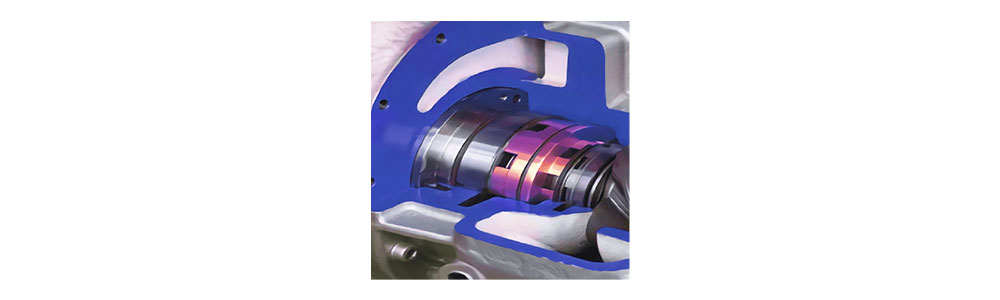

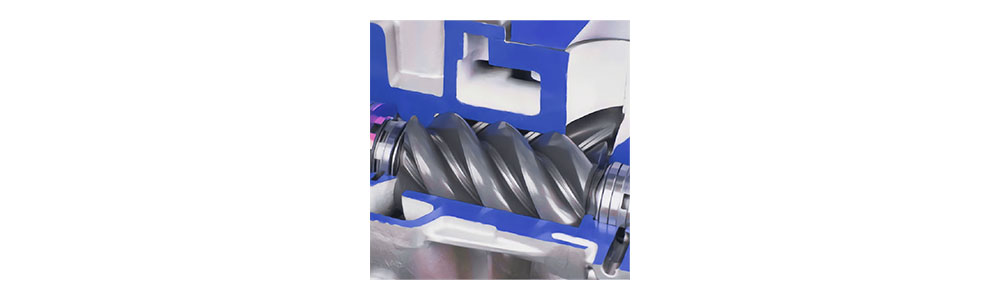

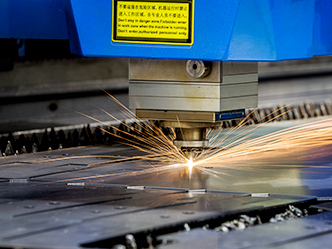

3 Super Coated Stainless Steel Rotor

Use stainless steel as the rotor material to ensure the life and stable operation of the machine head. The inner wall of the rotor and the compression chamber is coated with a strong, super coating UltraCoatTM, which improves the reliability of the compressor and the quality of compressed nitrogen.

-

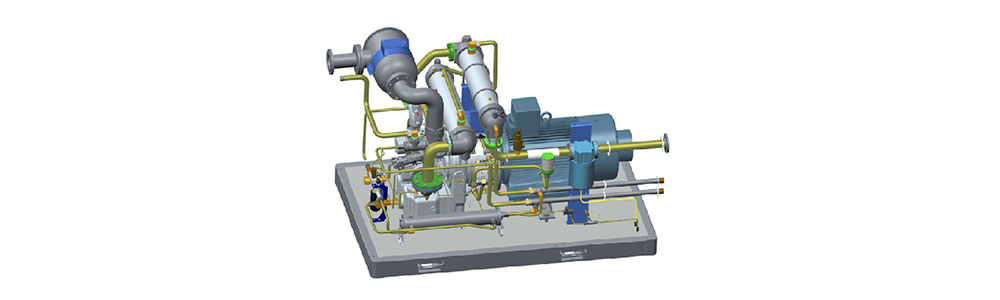

4 motor

High-efficiency standard TEFC motor, IP55 Protection grade, F insulation grade, VSD motor is option for the VSD control.

-

5 intake filter

The intake filter adopts a special pressure-bearing design to ensure that the intake pressure is 1Bar without leakage.

-

6 Siemens core electrical components

Reliable Siemens core electrical control components ensure long-term stable operation of the unit, and all-round safety protection from pressure, temperature, current, mechanical transmission, etc. is adopted to ensure mechanical and personal safety.

-

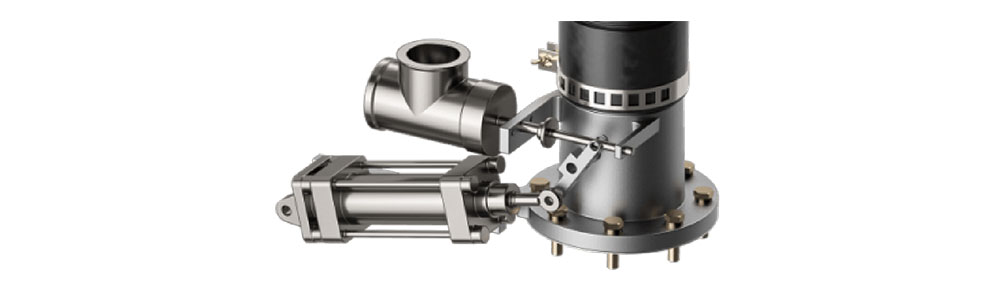

7 Efficient intake valve design

The hydraulic adjustment mechanism replaces the pneumatic adjustment mechanism, which avoids the regular replacement of pneumatic components and reduces unnecessary downtime and maintenance costs.

-

8 Venture tube

Effectively prevent pressure, flow and avoid high-frequency sound due to airflow pulsation and vibration.

-

9 Color touch display

7-inch high-definition color LCD touch screen, real-time monitoring of compressor running status, system flow chart display is clear and intuitive, friendly man-machine interface design.

-

10 Online remote monitoring(Option)

Through the mobile phone APP, you can grasp various data of the compressor's operating status with one click, realize preventive maintenance, and have higher operating energy efficiency.