- home

- About us

Company ProfileclientsHonors & CertificatesCompany Tourvideo center

- Products

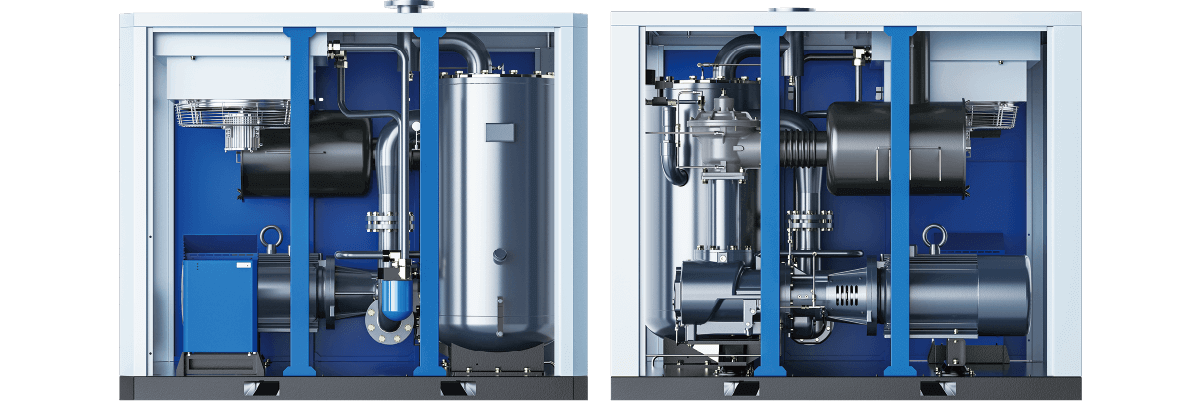

Oil Injected Screw Compressor PM SeriesOil Injected Two Stage Screw CompressorOil Injected Low Pressure Screw CompressorOil Free Air CompressorOil Free Nitrogen CompressorMagnet Bearing Turbo Blower & CompressorOil injected VSD Vacuum PumpDiesel Portable CompressorDownstream Equipment

- solutions & cases

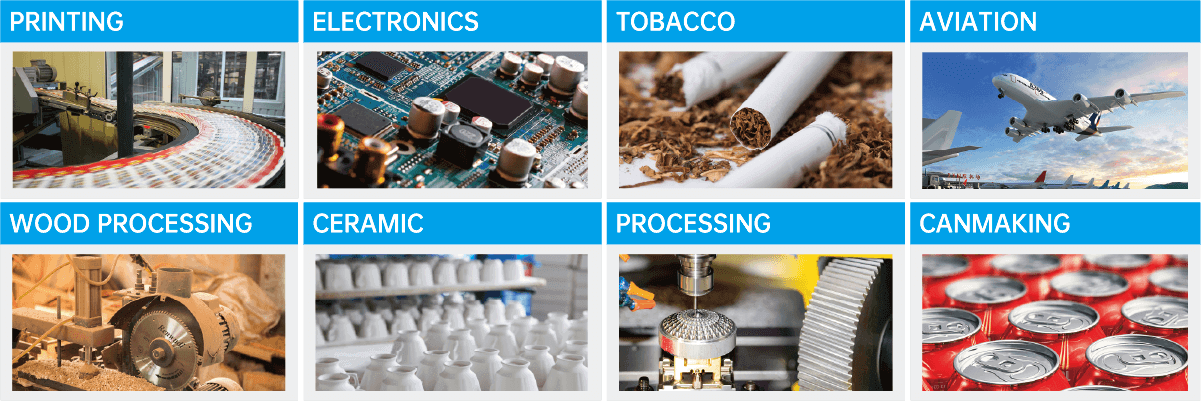

Pharmacy IndustryManufacturing IndustryPower Station IndustryCement IndustryTextile IndustryAutomotive IndustryHealth Industry

- Distributor

- Service

- News

- Contact