-

1 HIGH AND NEW TECHNOLOGY

● Adopt active magnetic bearing system, no contact, no lubrication, no maintenance;

● The speed is controlled by a high-performance frequency converter, and control modes can be selected;

● Using advanced control system, monitoring the running status in real time, and can be controlled remotely,unattended operation;

● The fully enclosed air-cooling and water-cooling system is used to dissipate heat from the motor to ensure that the fan is in a stable and efficient operating state and prolong the service life of the equipment. modular design, convenient and quick maintenance.

-

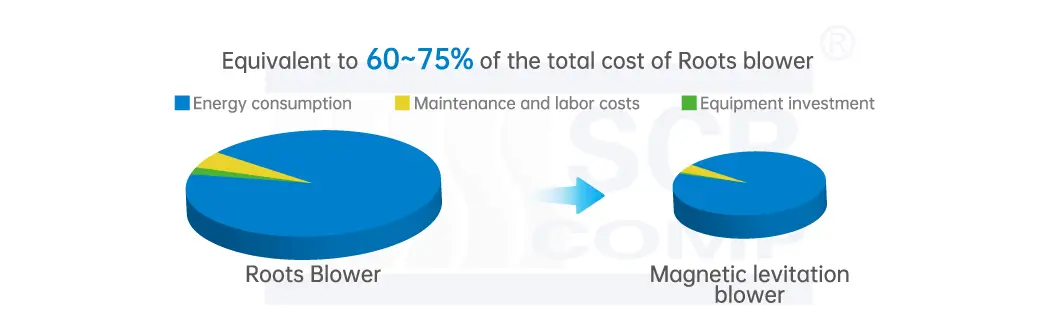

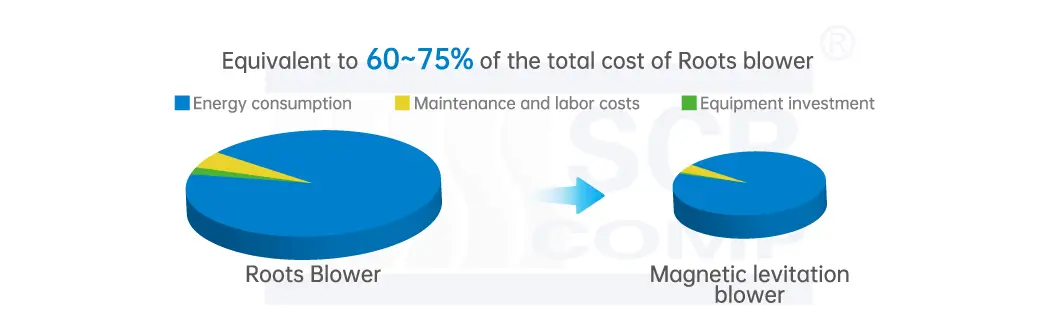

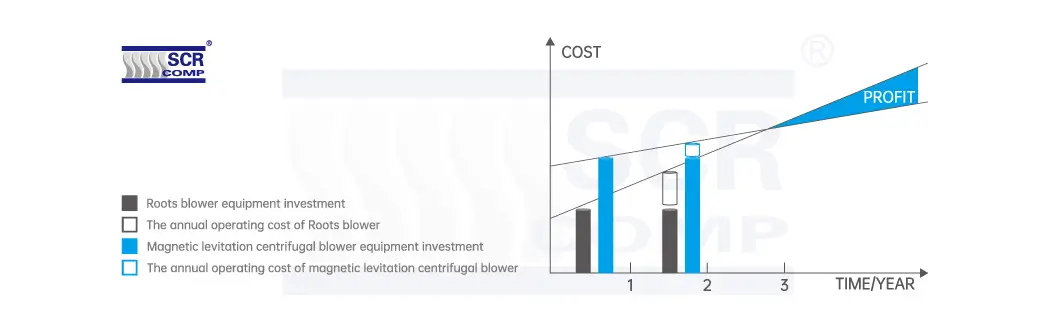

2 ENERGY SAVING

● Compared with the Roots blower, the efficiency of the magnetic levitation blower is better than 30%~40%;

● Taking the 100KW maglev centrifugal blower as an example, compared with the Roots blower, each maglev centrifugal blower can save more than 300,000 KWH electricity and more than 30,000 dollar in electricity costs every year.

-

3 ECO-FRIENDLY

● The magnetic levitation blower and compressor do not need lubrication, and the compressed air is clean, oil-free and pollution-free;

● The magnetic bearing is completely frictionless and has low operating noise, which will not affect the surrounding environment;

● Taking a 100kw maglev blower as an example, each blower can reduce carbon dioxide emissions by about 275 tons per year.

-

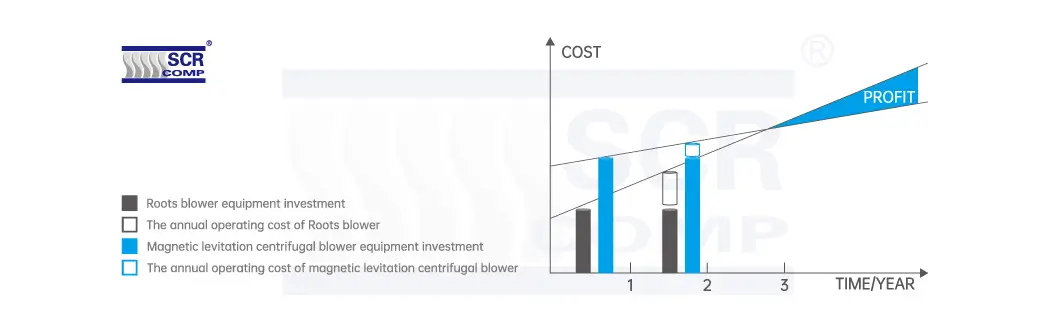

4 LOW-COST OPERATION

The magnetic bearing is completely frictionless, reducing the probability of product damage, and the service life is more than 25 years;

Easy to maintain and only need to replace the filter regularly;

Do not need a lubrication system, which saves the use, treatment, and cleaning of lubricating oil;

The motor adopts direct drive, compact structure, small floor space, light weight.