Oil Injected Fixed Speed Compressor+

-

about us

Company Profile clients Honors & Certificates Company Tour video center

-

products

Oil Injected Screw Compressor PM Series Oil Injected Two Stage Screw Compressor Oil Injected Low Pressure Screw Compressor Oil Injected Fixed Speed Compressor Oil Free Air Compressor Oil Free Nitrogen Compressor Magnet Bearing Turbo Blower & Compressor Oil injected VSD Vacuum Pump Diesel Portable Compressor Downstream Equipment

-

cases

Pharmacy Industry Manufacturing Industry Power Station Industry Cement Industry Textile Industry Automotive Industry Health Industry

-

technical service

safety notice compressed air system installation installation guide maintenance

-

news

Belt Driven Series Compressor M series

Working Power: 5.5~75KW(7.5-100HP)

Free Air Delivery: 0.6~13.3m^3/min(21.2~469.7cfm)

Working Pressure: 7/8/10/12.5bar(101.5/116/145/181.3 psig)

-

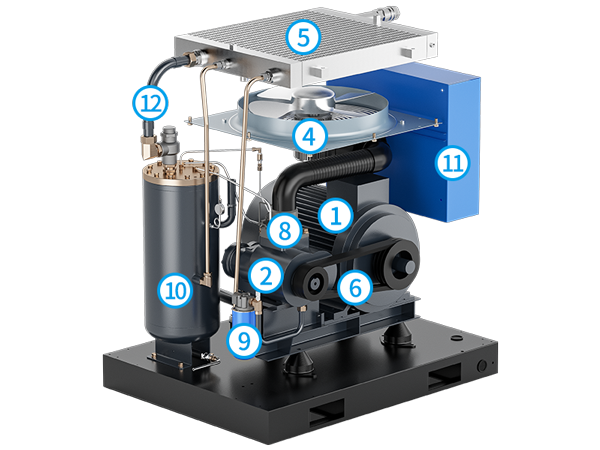

1 High reliable airend

Machined by high precision CNC machine, and inspected by high precision 3D inspection machine. High reliability onsite proofed in the market more than 13years, 5:6Profile rotor equipped with world famous bearing.

-

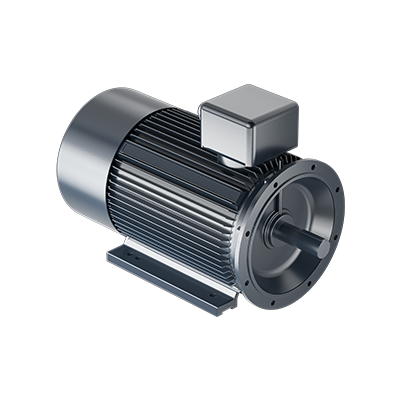

2 IEC standard TEFC Motor

TEFC, IP 54(IP 55 Optional) Protection Grade, F Grade Insulation, S1 Duty ensures stable running even in 24hour / 7 day applications. Top quality SKF motor bearings ensure long service life.

-

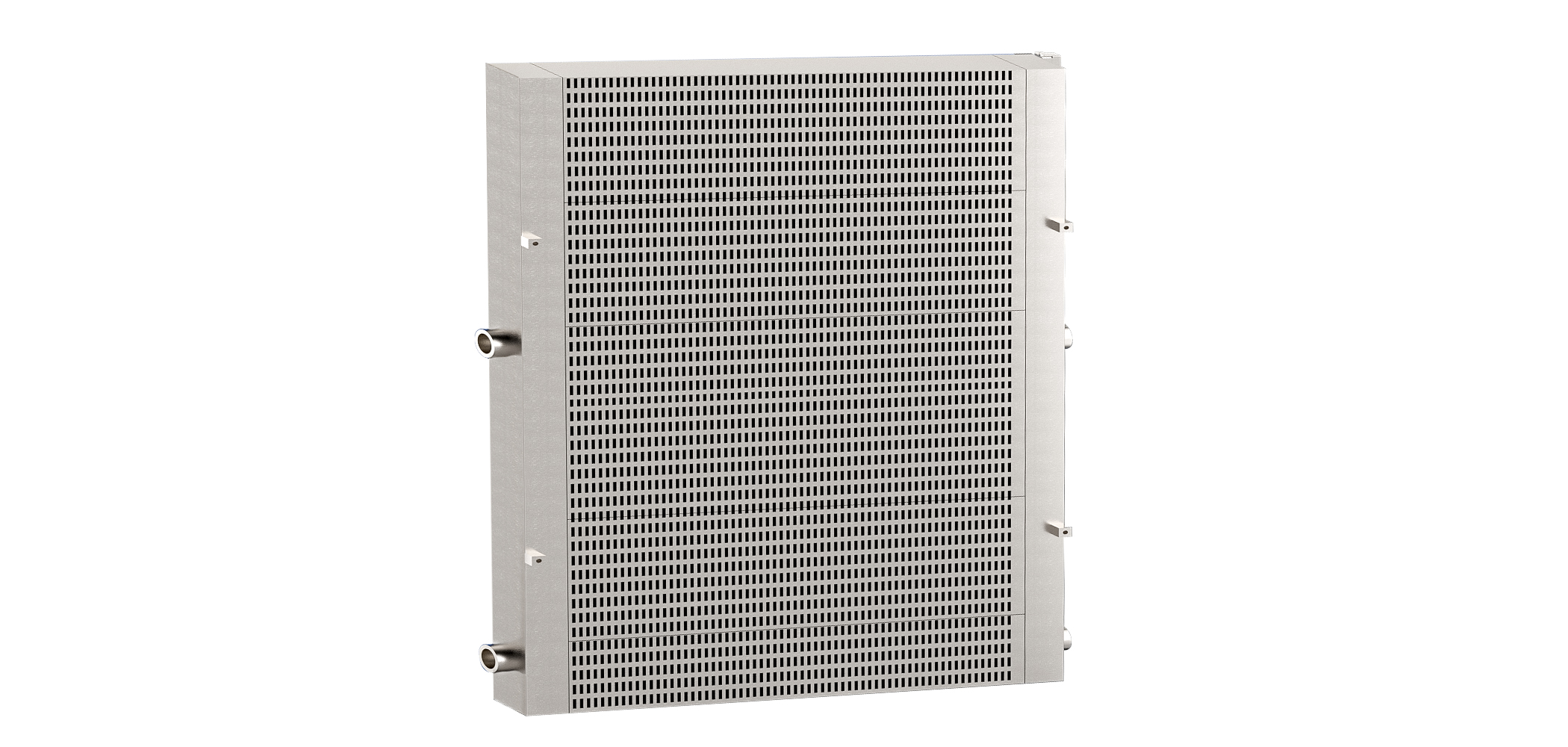

3 Oversized cooler

Oversized cooler with 30% reserve margin, ensures excellent cooling even under high ambient conditions, it’s more than 10years proofed in the tropical country, like UAE, Saudi Arabia etc.

-

4 Siemens core components

1. Oversized Siemens contactors are selected, it’s for stable operation to ensure longevity, even in the heaviest duty applications.

2. Intelligent PLC control, monitors all key running parameters of the compressor. The PLC reports on 12 alarms and 13 security protection.

-

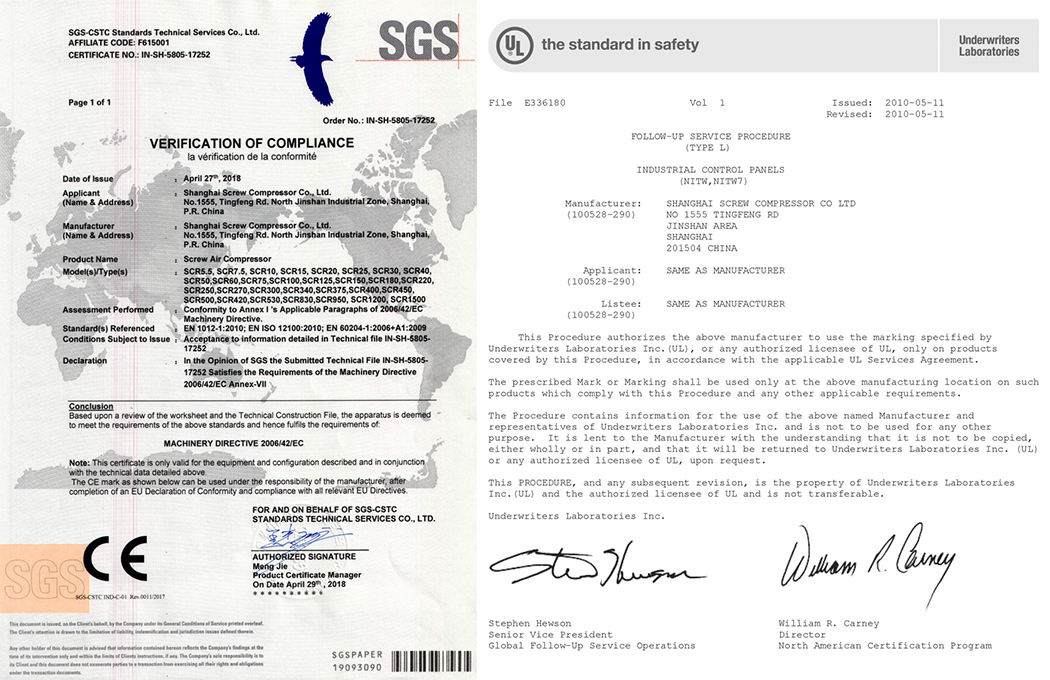

6 World CE/UL Certificate

-

- ① Premium Efficiency Drive Motor ● Premium efficiency Totally Enclosed Fan Cooled (TEFC) IP54/IP55 motor (Class F insulation) protects against dust and chemicals etc. ● Long-term stable operation even in harsh environments up to 55℃ (131℉ )

-

- ② State-of-the-art Screw Element ● Original airend oAdvanced SAP profile design ● The material of the rotors is American specialty steel ● Superior Sweden SKF element bearings

-

- ③ Superior Air Filter ● Superior air filter with two-stage dust removal and filtering system with efficiency of up to 99.9% even in heavy-duty environments ● Extends the service life of the compressor parts and components, ensures high air quality

-

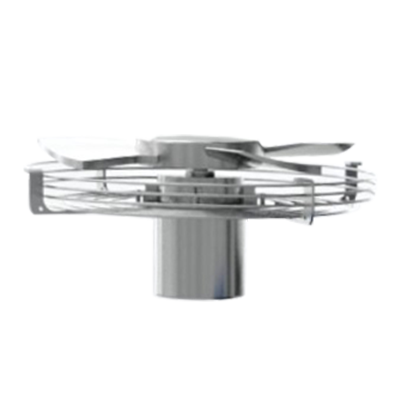

- ④ cooling fan ● Low noise level ● High capacity for optimized cooling ● Low power consumption

-

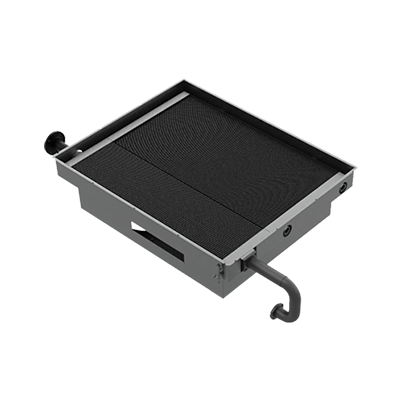

- ⑤ Oversized cooler design ● Easy access for maintenance ● Paint anti-corrosion coating on surface ● Over size cooler design

-

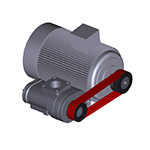

- ⑥ Belt Driven ● Germany Optibelt brand belts ensure the high performance and easy maintenance

-

-

⑦ Intelligent SPC200 Controller ● User Friendly Interface, real-time operation/maintenance/alarm information.

● Self-protection & Intelligent automatic control, provide 12 alarms and 13 security protection.

-

-

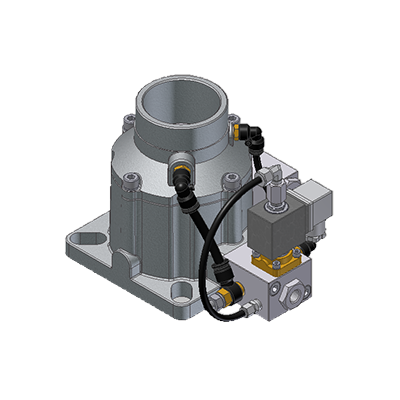

⑧ Inlet valve ● Advanced & Robust Suction valve designed for heavy duty running.

● Reliable solenoid valve, service life up to 2 million actions.

● Simple layout and easy to maintain.

-

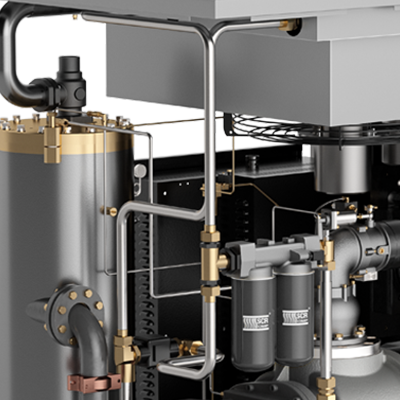

- ⑨ Oil filter ● Filter the dirts in the lubricated oil reliably ● Oil particles can be controlled at 0.1 micron ● Ensure the smooth and well-lubricating oil system

-

- ⑩ Oil gas tank & Built-in separation system ● Oversized air and oil tank improves the cyclone effect maximising the seperation process ● The high efficiency oil seperator ensures that the oil carry over is less than 3ppm. ● System pressure loss:less than 0.02Mpa

-

- (11) electrical control cabinet ● Siemens core electrical components are used to further enhance reliabity.

-

- (12) all-steel internal pipe system ● All steel internal pipe work is used to prevent leakage and premature ageing often seen with flexible pipes ● Less pipe pressure loss

| Model | KW | HP |

Capacity (m3/min) |

Pressure (BAR) |

Dimension(mm) | Weight(KG) | Size |

| SCR7.5M-7 | 5.5 | 7.5 | 0.85 | 7 | 900*680*970 | 250 | R 1/2 |

| SCR7.5M-8 | 0.8 | 8 | |||||

| SCR7.5M-10 | 0.7 | 10 | |||||

| SCR7.5M-12.5 | 0.6 | 12.5 | |||||

| SCR10M-7 | 7.5 | 10 | 1.1 | 7 | 900*680*970 | 250 | R 1/2 |

| SCR10M-8 | 1 | 8 | |||||

| SCR10M-10 | 0.9 | 10 | |||||

| SCR10M-12.5 | 0.8 | 12.5 | |||||

| SCR15M-7 | 11 | 15 | 1.6 | 7 | 800*950*1130 | 380 | R 3/4 |

| SCR15M-8 | 1.5 | 8 | |||||

| SCR15M-10 | 1.4 | 10 | |||||

| SCR15M-12.5 | 1.2 | 12.5 | |||||

| SCR20M-7 | 15 | 20 | 2.3 | 7 | 800*950*1130 | 420 | R 3/4 |

| SCR20M-8 | 2.2 | 8 | |||||

| SCR20M-10 | 1.9 | 10 | |||||

| SCR20M-12.5 | 1.7 | 12.5 | |||||

| SCR25M-7 | 18.5 | 25 | 3.4 | 7 | 900*1150*1350 | 560 | R1 |

| SCR25M-8 | 3 | 8 | |||||

| SCR25M-10 | 2.7 | 10 | |||||

| SCR25M-12.5 | 2.4 | 12.5 | |||||

| SCR30M-7 | 22 | 30 | 3.8 | 7 | 900*1150*1350 | 580 | R1 |

| SCR30M-8 | 3.5 | 8 | |||||

| SCR30M-10 | 3.2 | 10 | |||||

| SCR30M-12.5 | 2.8 | 12.5 | |||||

| SCR40M-7 | 30 | 40 | 5.1 | 7 | 900*1150*1350 | 640 | R1 |

| SCR40M-8 | 5 | 8 | |||||

| SCR40M-10 | 4.2 | 10 | |||||

| SCR40M-12.5 | 3.7 | 12.5 | |||||

| SCR50M-7 | 37 | 50 | 6.5 | 7 | 1000*1300*1470 | 800 | R1 1/2 |

| SCR50M-8 | 6.2 | 8 | |||||

| SCR50M-10 | 5.7 | 10 | |||||

| SCR50M-12.5 | 5.1 | 12.5 | |||||

| SCR60M-7 | 45 | 60 | 7.7 | 7 | 1000*1300*1470 | 920 | R1 1/2 |

| SCR60M-8 | 7.5 | 8 | |||||

| SCR60M-10 | 6.8 | 10 | |||||

| SCR60M-12.5 | 6 | 12.5 | |||||

| SCR75M-7 | 55 | 75 | 10.4 | 7 | 1600*1350*1700 | 1540 | R2 |

| SCR75M-8 | 9.4 | 8 | |||||

| SCR75M-10 | 8.4 | 10 | |||||

| SCR75M-12.5 | 7.8 | 12.5 | |||||

| SCR100M-7 | 75 | 100 | 13.3 | 7 | 1600*1350*1700 | 1650 | R2 |

| SCR100M-8 | 13 | 8 | |||||

| SCR100M-10 | 11.9 | 10 | |||||

| SCR100M-12.5 | 10 | 12.5 |

-

Note:

The capacity is measured as GB3853 standard.(equivalent to ISO1217 Annex C)

Standard voltage is 380V/50HZ/3P, other voltage is available.

The recommended best capacity range is 60%-100%.

Alpine/high altitude, high temperature, high huidity, high dust loads or other adverse working conditions will require specialized custom designs. These are available on special request.

We reserve the right to make changes and improvements to the design and appearance.

Specifications may change without prior notice.