Oil Free Screw Compressor+

-

about us

Company Profile clients Honors & Certificates Company Tour video center

-

products

Permanent Magnet Screw Compressor PM Series Oil Free Screw Compressor Two stage screw compressor H series Low pressure screw compressor Nitrogen compressor Traditional Screw Compressor Downstream Equipment

-

cases

Pharmacy Industry Manufacturing Industry Power Station Industry Cement Industry Textile Industry Automotive Industry Health Industry

-

technical service

safety notice compressed air system installation installation guide maintenance

-

news

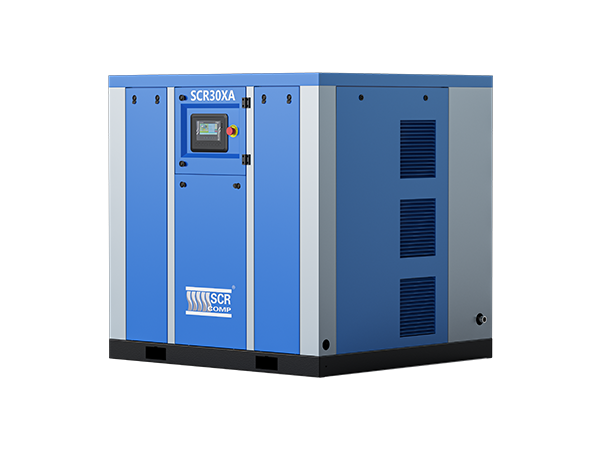

Oil Free Scroll Compressor XA series

Working Power: 3.7-30KW(5-40HP)

Free Air Delivery: 0.35-3.5m³/min(12.3~123.6cfm)

Working Pressure: 8/10bar(116/145psig)

-

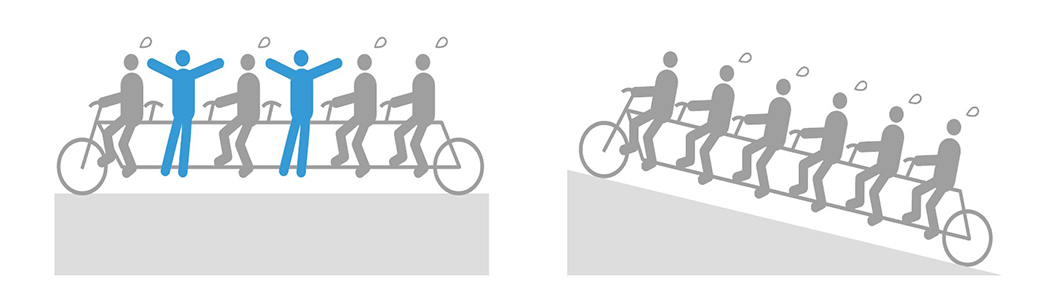

1 Energy Saving

Depends on multi-level control, realized better operation and energy saving.

Multiple compressors are built into one canopy. According to the compressed air usage amount , take use of a better number of free operation through the multi-stage control, so as to avoid unnecessary operation to realize energy saving.

Multi stage control has the energy saving ability beyond frequency conversion control.

Take use of on/off control with minimum energy consumption. According to the air usage and the actual situation to achieve better operation, Significantly reduce power consumption, better energy saving effect.

-

2 Japan Original Anest Iwata Airend

Original Made-in-Japan Anest Iwata airend, highest quality standard in the world, Simple structure, easy maintenance. Low noise and fast air supply, Airend does not need oil cooling and lubrication to realize true oil-free.

-

3 Airend Structure:

Simple structure, Orbiting scroll & Fixed scroll realize compression process, no friction.

-

4 SCR9000 Touch screen controller

1.7" touch screen PLC, easy for operation.

2.Full features protection, including over temp. Protection, over pressure protection, motor overload, phase unbalance etc. more than 13itmes protection.

3.Support intelligent control, such as running schedule, auto startup after power failure.

4.Support Modbus RTU, and can realize remote monitoring.

-

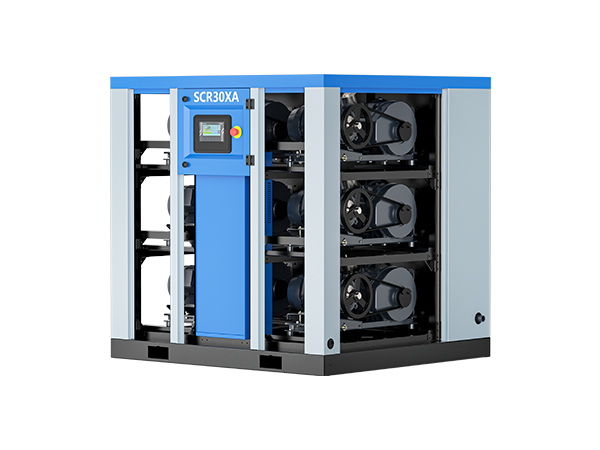

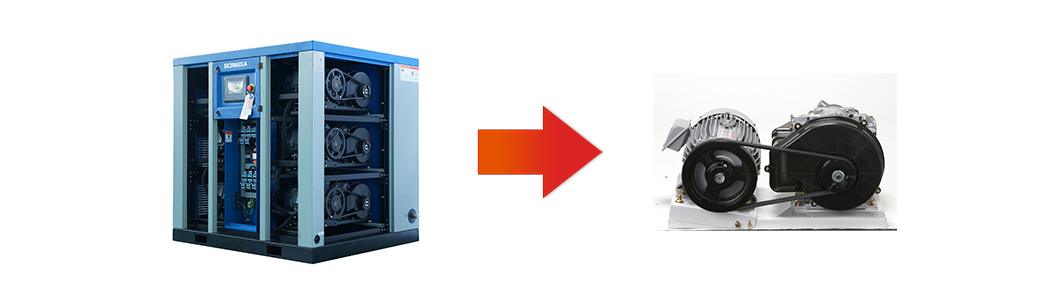

5 Compressor Layout

Compressor is combined by multiple airend+motor together, each one realize independent driven and control, more safe operation.

-

-

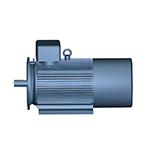

① Motor

● Standard TEFC motor specially design for heavy duty application.

-

● IP54(IP55 option) protection grade ensure the stable running even at dusty environment.

-

● Reliable quality proofed in the market more than 15years.

-

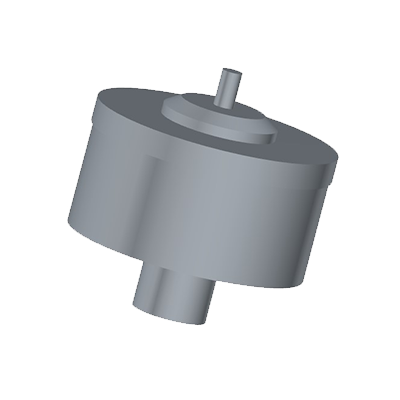

- ② Airend ● Japan Anest Iwata oil-free scroll compressor airend, imported bearings and grease ● High precision processing of moving vortex disk, static vortex disk and shell to ensure the high efficiency of the airend

-

- ③ inlet filter ● Filtration accuracy up to 99.5% ● Dust particles below 0.3 micron ● Pressure drop indicator

-

-

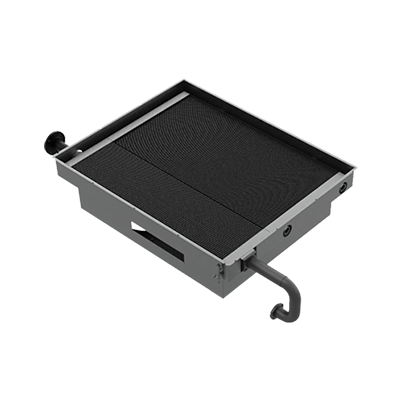

④ Classic cooler design

●High reliability air cooler designed for high temp. air, can resist up to 280degree.

● Easy access for maintenance

● Paint anti-corrosion coating on surface

-

- ⑤ SCR9000 Touch Screen PLC ● 7.0 inch full color touch LCD screen ● Real-time Operation/ Maintenance/ Alarm information ● Operation record/ Chart display ● Weekly timer/Service history and planning

-

- ⑥ electrical control cabinet ● Siemens core electrical components are used to further enhance reliabity.

| Model | KW | HP |

Capacity (m3/min) |

Driven Method |

Outlet Temp (C) |

Stainless Steel Air Receiver Capacity(L) |

Power Supply (V) |

Dimension (mm) |

Weight (kg) |

Outlet Size |

| SCR5XA-8/10 | 3.7 | 5 | 0.4/0.35 | Belt Driven | Ambient Temp+15 | 50 | 380 | 1100*650*980 | 230 | Rc3/4 |

| SCR10XA-8/10 | 7.5 | 10 | 0.8/0.7 | 230 | 1200*650*998 | 280 | Rc3/4 | |||

| SCR15XA-8/10 | 11 | 15 | 1.2/1.0 | No | 1300*740*1403 | 450 | Rc1 | |||

| SCR20XA-8/10 | 15 | 20 | 1.6/1.4 | No | 1300*740*1808 | 650 | Rc1 | |||

| SCR30XA-8/10 | 22 | 30 | 2.6/2.1 | No | 1400*13400*1410 | 900 | Rc1 | |||

| SCR40XA-8/10 | 30 | 40 | 3.5/2.8 | No | 1400*1300*18080 | 1300 | Rc1 |

-

Remarek:

Capacity is measured under rated pressure, following ISO1217 C Annex.

Alpine/high altitude, high temperature, high humidity, high dust loads or other adverse working conditions will require specialised custom designs.These are available on special request.

We reserve the right to make changes and improvements to the design and appearance.Specifications may change without prior notice.